Project Name

How Ksolves Enabled Compressor Short Cycling Detection Using Machine Learning?

![]()

Our client is an HVAC (Heating, Ventilation, and Air Conditioning) service provider that specializes in high-quality HVAC systems. They have a critical business imperative to optimize compressor performance and reliability by harnessing AI/ML techniques, specifically focusing on detecting short cycles in their compressor units.

- Disruptions or anomalies within the dataset can challenge the client's ability to work with reliable data.

- The client encounters a substantial challenge stemming from improperly labeled data, which hinders their ability to address the issue of detecting short cycles in compressors effectively.

- Identifying and detecting short cycles in the compressor poses a significant challenge for the client.

We provided a comprehensive solution to our clients that helped them to solve all the complex challenges. Some of those solutions are:

- We employed data extraction and data cleansing techniques to assist the client in overcoming their challenges related to data quality, ensuring more accurate short-cycle detection.

- Leveraging the XGBoost Library, we developed and trained a robust machine-learning model to process the enhanced data, which helped us identify short cycles in compressors.

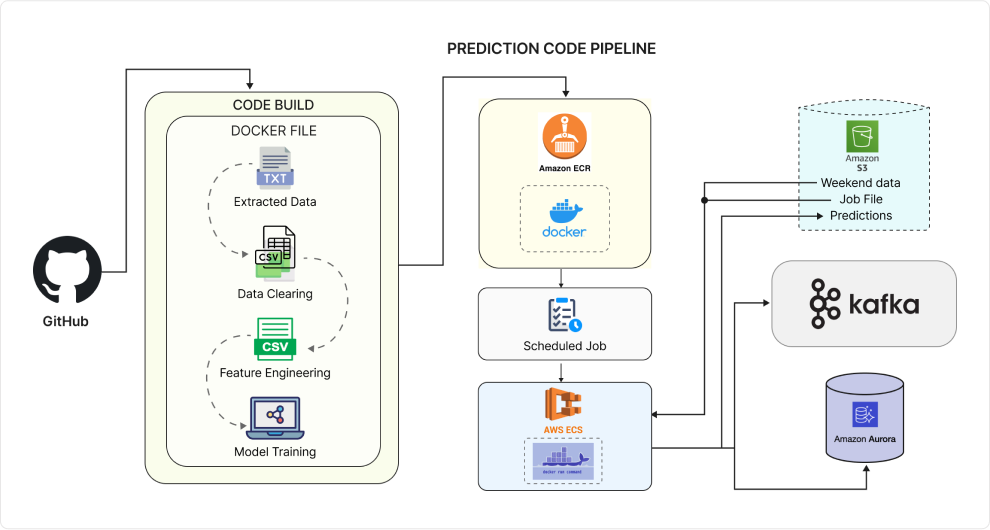

- We facilitated the deployment of the solution by integrating it with GitHub and utilizing AWS CodePipeline, streamlining the process and ensuring efficient code deployment to AWS auto-scaling.

- To optimize resource utilization, we implemented a scheduler that dynamically scales up or down the number of running services in Amazon Elastic Container Service (ECS) based on predefined time triggers.

- We created a service within AWS ECS to run multiple services as containers within a Fargate cluster, enhancing the efficiency and manageability of the deployment.

- The AWS Application Autoscaling service was configured to operate for a predefined duration. Based on demand, it automatically adjusted the number of running services. The service gracefully stopped running once the designated time elapsed to optimize resource usage.

Leveraging AI and ML technologies for Compressor Diagnosis, we developed a model with an F1 score of 0.86 and implemented it in production. This transition marked a significant shift from a “fail and fix” approach to a more intelligent solution. It allowed our client to proactively monitor and improve model performance, leading to more informed and effective decision-making.

Enhance Your Business Operations With Our Custom Machine Learning Model Solutions!