How Big Data is Reshaping the Manufacturing Industry: 7 Key Examples

Big Data

5 MIN READ

July 12, 2024

![]()

Have you ever wondered how manufacturers are using data to make smarter decisions and improve their processes? The answer is Big Data. The manufacturing industry is always looking for ways to streamline operations, optimize production, and cut costs. Big Data is quickly becoming an essential tool in achieving these goals.

By collecting and analyzing massive amounts of data from various sources, manufacturers can gain valuable insights into their operations, identify areas for improvement, and make informed decisions that can increase efficiency and profitability. In this blog, we will dive into seven examples of how Big Data analytics is transforming the manufacturing industry.

Read: Top Big Data Analytics Trends 2024

Benefits of Big Data in the Manufacturing Industry

The manufacturing industry is undergoing a revolution due to Big Data analytics. By utilizing data from various sources, manufacturers can gain insights into their production processes, optimize their supply chain, reduce costs, and improve the quality of their products. Big Data analytics can also help manufacturers predict maintenance needs, prevent downtime, and create a safer work environment.

Also Read: Benefits of Big Data in Supply Chain Management

Moreover, the use of Big Data in manufacturing has enabled manufacturers to make data-driven decisions that can drive growth and profitability. With the right approach to Big Data, manufacturers can improve operational efficiency, and reduce waste. With the right tools and processes in place, Big Data analytics can drive growth and profitability while helping manufacturers stay ahead of the curve in an increasingly data-driven world.

Challenges of Big Data in the Manufacturing Industry

Big Data analytics has the power to transform the manufacturing industry but it also comes with multiple challenges. Let’s understand them:

1. Data Volume, Variety, and Velocity (The 3 Vs):

The manufacturing industry works on producing a large amount of data from sensors, machines, and various other sources. In addition, the data comes from various sources in different formats (structured, semi-structured, unstructured) that need to be processed and analyzed to provide valuable insights. If we talk about traditional data infrastructure, then there is a struggle to handle the complexity.

2. Data Integration and Silos:

The manufacturing data often resides in isolated systems like SCADA (Supervisory Control and Data Acquisition) and ERP (Enterprise Resource Planning). We can integrate data from these disparate sources and create a unified view for big data analytics.

3. Data Quality and Security:

It is necessary to ensure the data quality through a proper data cleansing process. However, the inaccurate and incomplete data showcase invaluable insights and lead to poor decision-making. However, when the amount of data increases, it will lead to more security concerns. By implementing the robust cybersecurity measures, it is necessary to protect the crucial data.

4. Skilled Workforce:

A high-value staff with knowledge of big data technology, data science, and analysis is crucial for the success of big data initiatives. To remove the space, manufacturers must focus on the training for the current employees or recruit data specialists.

5. Cost of Implementation:

The implementation of big data analytics solutions needs much investment in infrastructure, software, and talent part. This is considered as an upfront cost for manufacturers especially when they belong to small and medium-scale enterprises.

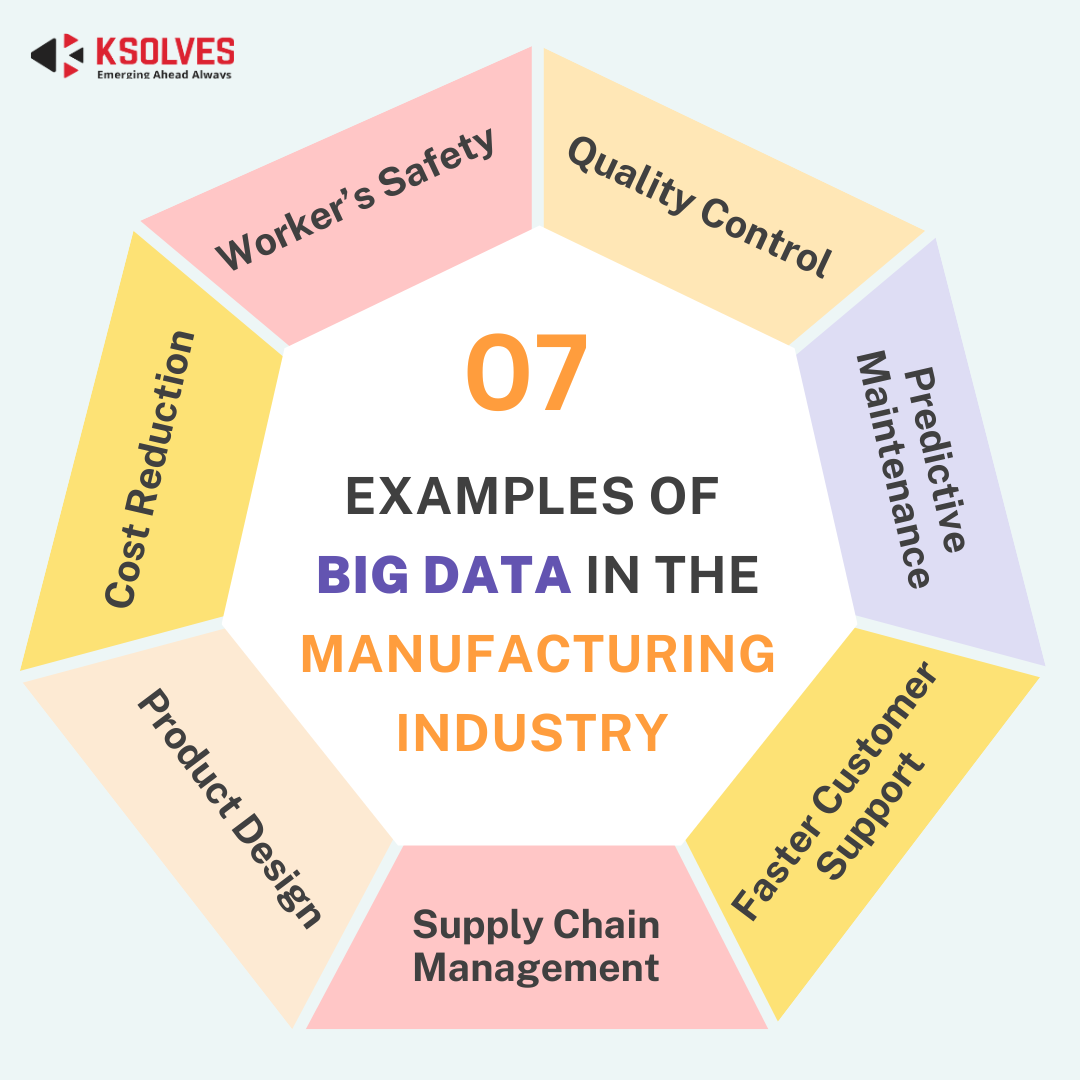

7 Examples of Big Data Improving Manufacturing Industry

1. Quality Control

Big Data analytics can be quite helpful in assuring quality control, which is a crucial step in the manufacturing process. Manufacturers can monitor and analyze manufacturing processes to find abnormalities, faults, or other problems that could compromise product quality by gathering data in real time from sensors and other sources.

Manufacturers can acquire deeper insights into the data and identify concerns before they become serious issues by utilizing advanced analytics technologies. With this knowledge, producers can react promptly to make changes and guarantee that their goods satisfy the highest standards. Manufacturers can improve product quality, decrease waste, and boost productivity by employing Big Data analytics for quality control, which will ultimately result in higher customer satisfaction and increased profitability.

2. Predictive Maintenance

Big Data can also help manufacturers to predict when maintenance is necessary to avoid breakdowns and downtime. By monitoring equipment and collecting data from various sensors and sources, manufacturers can analyze patterns and trends to predict when maintenance is necessary. Unlike traditional maintenance methods that rely on fixed schedules or waiting for breakdowns to occur, predictive maintenance using Big Data analytics can help manufacturers avoid downtime, extend equipment lifespan, and prevent costly repairs.

By utilizing insights from Big Data analytics, manufacturers can optimize their maintenance schedules, ensuring that maintenance activities are performed at the right time to minimize disruption to production processes. Predictive maintenance using Big Data analytics can help manufacturers save time and money, improve efficiency, and increase equipment uptime, ultimately leading to better business outcomes.

3. Faster Customer Support

Big Data can also help manufacturers provide faster and more efficient service and support to their customers. With the help of Big Data analytics, manufacturers can establish a strong feedback loop with their customers, which is essential for building trust and long-term relationships.

By analyzing customer data, manufacturers can gain valuable insights into customer behavior, preferences, and satisfaction levels, enabling them to respond quickly and effectively to customer needs and concerns. This can help manufacturers to provide more personalized and relevant service and support, ultimately leading to higher customer satisfaction and loyalty. By leveraging Big Data in manufacturing for customer service, manufacturers can improve their overall business performance.

4. Supply Chain Management

Big Data plays a crucial role in optimizing supply chain management for manufacturers. By analyzing vast amounts of data on suppliers, inventory levels, and transportation, manufacturers can gain insights into their supply chain operations that were previously unattainable. This enables them to identify areas for improvement, reduce costs, and increase efficiency.

Also Read: Applications of Big Data in Supply Chain Management

By improving visibility into their supply chain, manufacturers can also make better-informed decisions, which can help them enhance their relationships with suppliers and improve customer satisfaction. With the help of Big Data analytics, manufacturers can optimize their supply chain and stay competitive in an ever-changing marketplace.

5. Product Design

Big Data is a powerful tool that can help manufacturers design and produce products that better meet the needs and preferences of their customers. By collecting and analyzing data from various sources such as social media, customer feedback, and market trends, manufacturers can gain insights into what their customers want and need.

This information can be used to create products that are more appealing to customers, leading to increased sales and revenue. This can help manufacturers build stronger customer relationships, improve brand loyalty, and drive business growth.

6. Cost-Reduction

Big Data analytics is a valuable tool for manufacturers to identify and eliminate inefficiencies in their production processes, leading to cost reduction and increased profitability.

By analyzing data from different sources, such as production logs, supply chain data, and equipment sensors, manufacturers can identify areas where costs can be reduced without sacrificing quality or efficiency. This data can help manufacturers optimize their production processes, reduce waste, and ultimately increase their profitability.

7. Worker’s Safety

One of the most significant benefits of Big Data analytics in manufacturing is its ability to improve worker safety. By monitoring worker behavior and identifying potential safety hazards, manufacturers can create a safer work environment for their employees. This is done by collecting data from various sources, such as sensors, wearables, and other devices, to identify risks such as workers being exposed to hazardous materials or operating machinery in an unsafe manner.

By analyzing this data, manufacturers can identify patterns and trends, and take corrective action to reduce the risk of accidents or injuries. This not only benefits the employees but also the company as a whole, by reducing worker compensation claims and improving productivity.

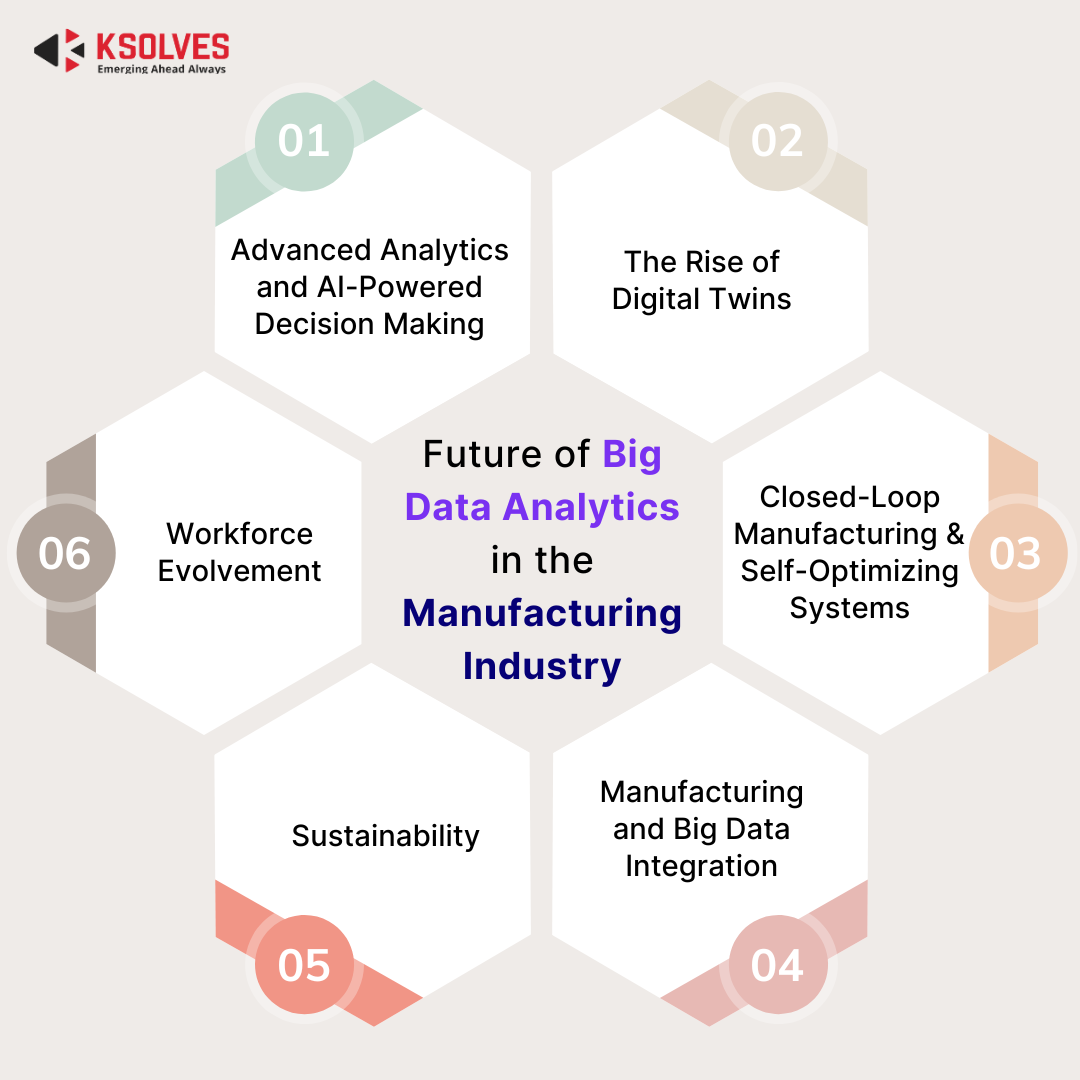

Future of Big Data Analytics in the Manufacturing Industry

Big Data Analytics has reshaped the future of the manufacturing industry. As the technology continues to evolve and the data becomes more extensive, we can expect how transformative applications emerge and go on.

Let’s discuss some possibilities that transform the manufacturing industry with Big Data analytics.

1. Advanced Analytics and AI-Powered Decision Making

By utilizing Artificial Intelligence, Big Data, and other Machine learning algorithms, the manufacturing process becomes automated. Big Data in this case will focus on processing the advanced analytics process that enables real-time decision-making and optimized production planning.

2. The Rise of Digital Twins

Digital twins are known as virtual replicas of physical machines and processes, it become even more sophisticated. Digital twins allow the integration of sensor data and real-time performance metrics for continuous simulation and optimization of the production process that leads to gain efficiencies.

3. Closed-Loop Manufacturing and Self-Optimizing Systems

Ecosystems for the manufacturing industry get increasingly closed-loop by transferring the data between the products, machinery, and the whole supply chain. It is possible for systems to self-optimize and make adjustments will the real-time data as per demand, resource availability, or product performance.

4. Manufacturing and Big Data Integration

The future of the manufacturing industry focuses on additive manufacturing (3D printing). In addition, the big data analytics industry plays an important role in optimizing the 3D printing process, personalizing designs, and managing complex material properties.

5. Sustainability

Big Data analytics forces the manufacturing industry to track the consumption of resources, identify the waste for waste reduction, and optimize the energy throughout the production process. This will work on contributing to the manufacturing practices and reduce the environmental footprint.

6. Workforce Evolvement

While working on the manufacturing automation process, human resources is considered a must. However, the workforce must have technical skills in data analysis, automation, and problem-solving along with traditional manufacturing expertise.

By utilizing this data-driven strategy, manufacturers work on maintaining higher business levels with efficiency, agility, and sustainability. Opting for Big Data analytics technology works to bring a productive and responsible environment.

Best Practices for Successful Big Data Implementation in Manufacturing

Implementing Big Data in manufacturing industries requires careful planning and execution to ensure success. Here are some best practices for Big Data implementation in manufacturing:

1. Start with clear business goals: Define your business goals and objectives and identify how Big Data can help you achieve them. This will help you to focus on the data that matters most and avoid getting lost in the vast amounts of data that are available.

2. Choose the right technology: Select the appropriate Big Data technology that aligns with your business needs and goals. Consider factors such as scalability, flexibility, security, and cost when choosing your Big Data solution.

3. Build a strong data infrastructure: Create a solid foundation for your data infrastructure that can handle the large amounts of data generated in manufacturing. This may involve investing in high-performance computing resources, data storage, and networking infrastructure.

4. Ensure data quality and security: Ensure that your data is accurate, complete, and secure. Implement data governance policies and procedures to ensure that data is properly managed and secured throughout its lifecycle.

5. Focus on actionable insights: Focus on the insights that can drive business value and avoid getting lost in the sea of data. Use data analytics to generate actionable insights that can help you to optimize processes, improve quality, reduce costs, and drive innovation.

Examples of Manufacturing Companies Successfully Using Big Data

1. Boeing

Boeing was facing issues with quality control and product development.

They utilize big data analytics in the manufacturing process to ensure high-quality standards and improve the product development process.

By analyzing the data from production lines and performing the QA tests, Boeing identifies the defect at early stages to improve manufacturing techniques. This automatically reduces the defects and improves the overall quality of the product.

2. Ford

Ford was facing issues with consumer insights and product customization.

They collect and analyze the data from all the connected vehicles to gain real-time insights as per consumer behavior and preferences. This helps the company to develop advanced features and customize the products as per the market demands.

The Impact of Big Data Analytics works on enhancing the customer experience, customizing the product, and improving the sales and market positioning.

Frequently Asked Questions

Why is Big Data Important for Businesses?

Big Data provides businesses with valuable insights and helps them make data-driven decisions. It can help businesses improve their operations, products, and services, increase efficiency, and drive revenue growth.

How is Big Data Collected in Manufacturing?

Big Data is collected in manufacturing through various sources, including sensors and IoT devices, production line systems, enterprise resource planning (ERP) systems, and customer feedback platforms.

What tools and technologies are used for Big Data Analytics in Manufacturing?

Tools and technologies used for Big Data analytics in manufacturing include Hadoop, Apache Spark, NoSQL databases, machine learning algorithms, and data visualization software.

Final Thoughts

In conclusion, we have learned how the usage of Big Data analytics in the manufacturing industries transformed it in multiple ways. By collecting and analyzing data from various sources, manufacturers can improve quality control, predict maintenance needs, provide faster customer support, optimize supply chain management, design better products, reduce costs, and improve worker safety.

With the right approach and implementation, manufacturers make informed decisions, increase efficiency, and drive business growth with Big Data. As the manufacturing industry continues to evolve, leveraging Big Data analytics will become increasingly critical for staying competitive and meeting the demands of a data-driven world.

Leveraging Apache Cassandra for Big Data in Manufacturing

As manufacturing companies continue to adopt big data analytics, having the right data infrastructure is crucial for handling massive, real-time data flows. Apache Cassandra is a powerful NoSQL database that enables efficient management of large datasets, ensuring scalability and high availability for mission-critical applications in the manufacturing industry.

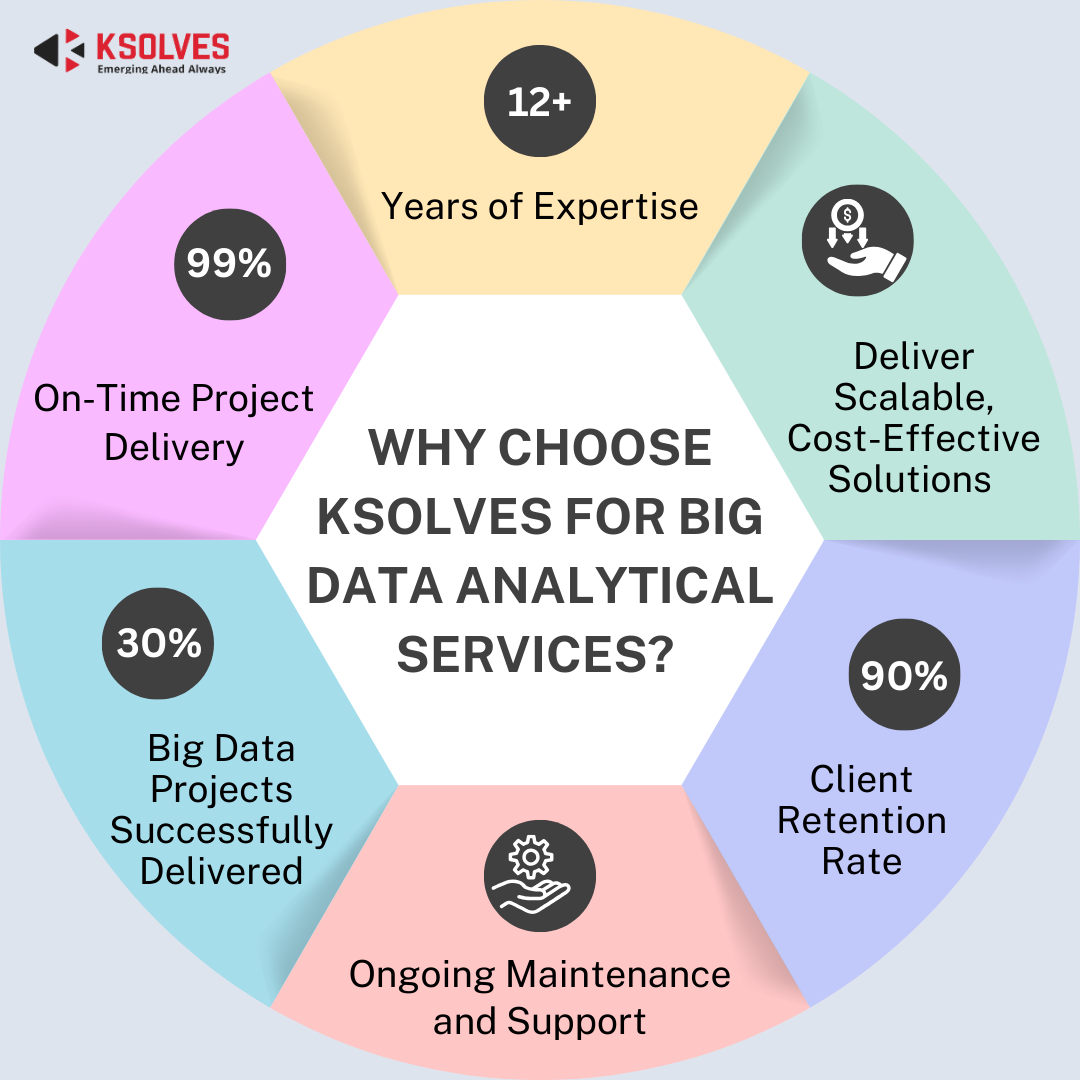

At Ksolves, we specialize in Apache Cassandra development services with a team of Datastax-certified experts and 50+ skilled developers. Whether it’s handling ongoing maintenance or delivering custom solutions, our 12+ years of experience and 30+ projects ensure success in your Cassandra journey.

Watch this video to learn more about how we can help your manufacturing business leverage Apache Cassandra for enhanced big data capabilities:

Partner with Ksolves for Reliable Big Data Analytical Services

Choosing Ksolves as your Big Data partner can be a game-changer decision for your business. With our expert team and cutting-edge technology, Ksolves can provide you with top-notch Big Data analytical services that can help you make data-driven decisions and gain valuable insights. Our services include data warehousing, data processing, data visualization, and more, ensuring that all your Big Data needs are met. Ksolves’ customer-centric approach, combined with their expertise, can help you unlock the full potential of your data and drive business growth. So, if you’re looking for a reliable and efficient Big Data partner, Ksolves is the way to go.

![]()

AUTHOR

Big Data

Anil Kushwaha, Technology Head at Ksolves, is an expert in Big Data. With over 11 years at Ksolves, he has been pivotal in driving innovative, high-volume data solutions with technologies like Nifi, Cassandra, Spark, Hadoop, etc. Passionate about advancing tech, he ensures smooth data warehousing for client success through tailored, cutting-edge strategies.

Share with