CRM for Manufacturing Industry: A Complete Guide

Summary

CRM is essential for modern manufacturing, helping businesses unify sales, production, inventory, and service on a single platform. By enabling accurate forecasting, process automation, and real-time visibility, manufacturing CRM improves efficiency, customer satisfaction, and revenue growth.

Introduction

Customer Relationship Management (CRM) refers to the strategies, processes, and technologies used to manage and analyze customer interactions throughout the entire customer lifecycle. What began as basic contact management tools in the 1990s has evolved into intelligent, cloud-based platforms powered by AI, analytics, and automation, helping businesses strengthen relationships and drive sustainable growth.

Adoption of CRM in the manufacturing industry comes with unique challenges. Long sales cycles, highly customized deals, complex distributor networks, extensive after-sales support, and the need to align sales, production, and inventory often lead to data silos and missed opportunities.

Specialized CRM solutions designed for manufacturing address these gaps by providing a 360-degree view of customers, integrating order history, service records, and real-time production data while enabling seamless collaboration across teams.

The global CRM market was valued at USD 73.40 billion in 2024 and is expected to reach USD 163.16 billion by 2030, growing at a CAGR of 14.6%. With CRM adoption reaching 86% in manufacturing, driven by digital transformation and AI, tailored CRM solutions are no longer optional but essential for staying competitive.

Why Manufacturing Industries Need CRM

Many manufacturing companies still rely on spreadsheets, emails, and disconnected systems to manage customer data. While these tools may seem sufficient, they lack scalability, visibility, and collaboration. A common misconception is that CRM software for the manufacturing industry is only useful for sales teams, making it appear irrelevant to production, operations, or service functions. This mindset often leads to resistance to change and concerns about complex implementations in an industry defined by long cycles and detailed processes.

As manufacturers move toward data-driven operations, manufacturing CRM software plays a critical role in delivering accurate customer insights, reliable demand forecasting, and operational efficiency. By centralizing customer interactions, order data, and historical trends, CRM supports better planning, optimized inventory levels, and reduced operational costs.

Most importantly, CRM connects sales, marketing, production, and service teams on a single platform. Real-time visibility into sales orders, production schedules, and inventory enables faster quote-to-delivery cycles, proactive service, and a more consistent customer experience.

Also Read: 10 Ways to Know Your Business Needs CRM

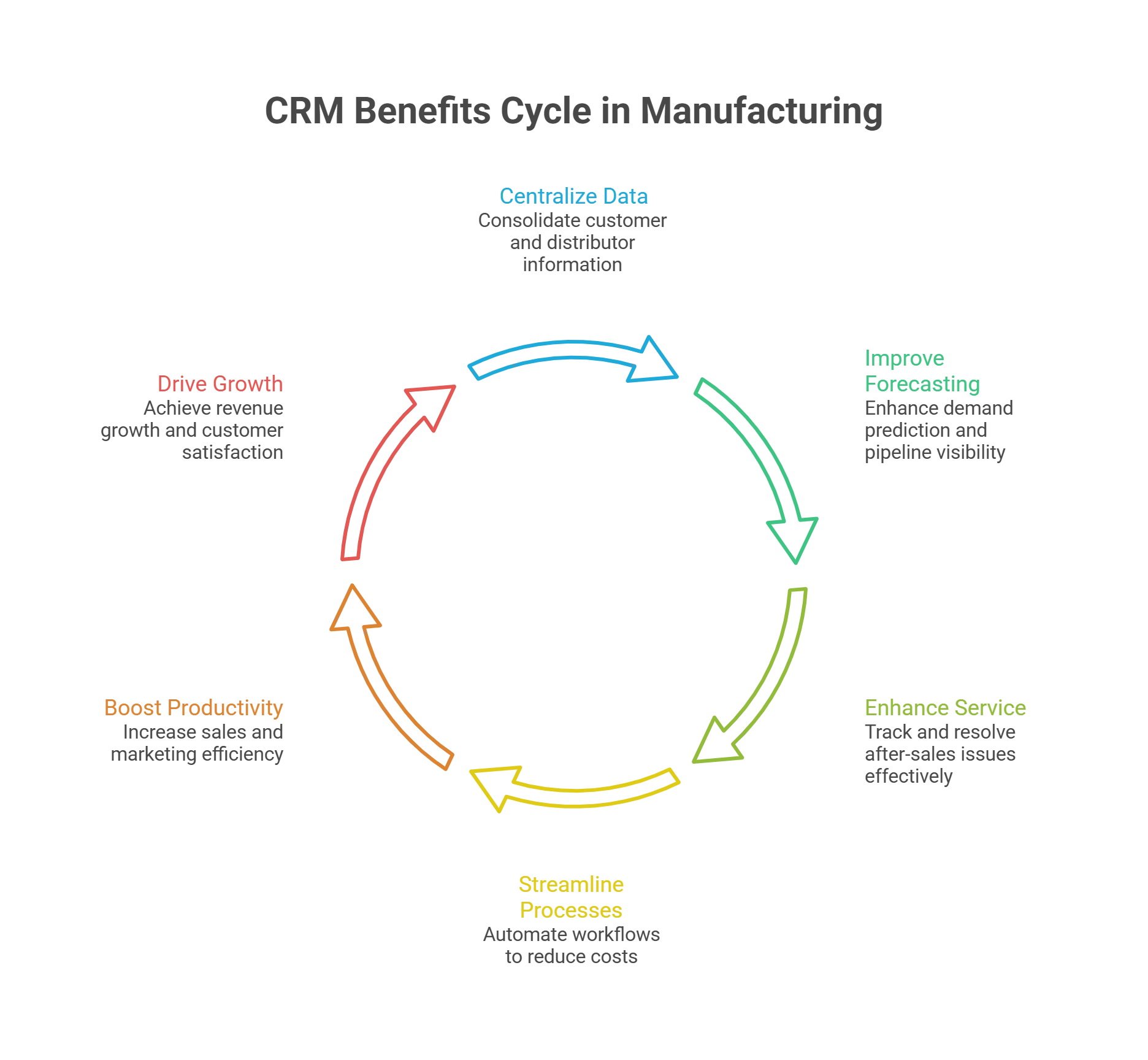

Key Benefits of CRM in Manufacturing

CRM systems deliver significant advantages to manufacturing companies by addressing industry-specific pain points and driving measurable improvements. Below are the primary benefits of CRM, explained in detail.

-

Centralized Customer and Distributor Data Management

Manufacturing often involves multiple touchpoints, including direct customers, distributors, dealers, and channel partners. A manufacturing CRM software centralizes all contact details, interaction history, quotes, orders, and preferences in one accessible platform. This eliminates scattered data across emails, spreadsheets, or individual laptops. Teams gain full transparency, reducing miscommunication, duplicate efforts, and errors. For example, production can instantly see a distributor’s order history, while sales avoids promising unavailable stock.

-

Improved Demand Forecasting and Sales Pipeline Visibility

Manufacturers deal with seasonal demand, custom orders, and long lead times. CRM in the manufacturing industry aggregates historical purchase patterns, current inquiries, and pipeline stages to provide accurate forecasting. Sales teams track deals from initial lead to closure with clear visibility into probabilities and timelines. This data helps production plan raw materials and capacity effectively, minimizing overstock or shortages and enabling proactive responses to market shifts.

-

Enhanced After-sales Service and Warranty Tracking

Post-sale support is critical in manufacturing due to warranties, maintenance contracts, and product complexity. CRM tracks service requests, warranty status, serial numbers, and resolution history. Service teams access the complete customer context, allowing faster and more accurate issue resolution. Automated reminders for preventive maintenance and quick complaint logging build long-term trust, increase customer retention, and open doors for upsell or cross-sell opportunities through positive service experiences.

-

Streamlined Processes Leading to Cost Reduction

Manual processes slow down quote generation, order processing, and approvals in traditional setups. Industrial CRM automates workflows such as lead assignment, quote approval, and order entry. This reduces administrative overhead, frees resources for higher-value tasks, and shortens sales cycles. Manufacturers report lower operational costs, better allocation of machinery and manpower based on real demand, and quicker conversion of leads into confirmed orders.

-

Boost in Sales Productivity

Sales representatives spend less time on data entry and more on selling thanks to mobile access, automated follow-ups, and task reminders. Marketing teams use CRM insights to create targeted campaigns based on customer segments and past behavior. Integrated analytics predict inventory needs accurately, preventing stockouts. Additionally, tracking competitor mentions or lost deals provides valuable market intelligence, helping refine pricing, features, and positioning.

-

Overall Revenue Growth and Customer Satisfaction

By consolidating data and insights, CRM for manufacturing empowers leadership with real-time dashboards and reports on sales performance, customer health, and profitability by product or region. Informed decisions lead to higher win rates, reduced churn, increased share of wallet with existing customers, and new revenue streams. Satisfied customers become advocates, providing referrals and repeat business in an industry where relationships drive long-term success.

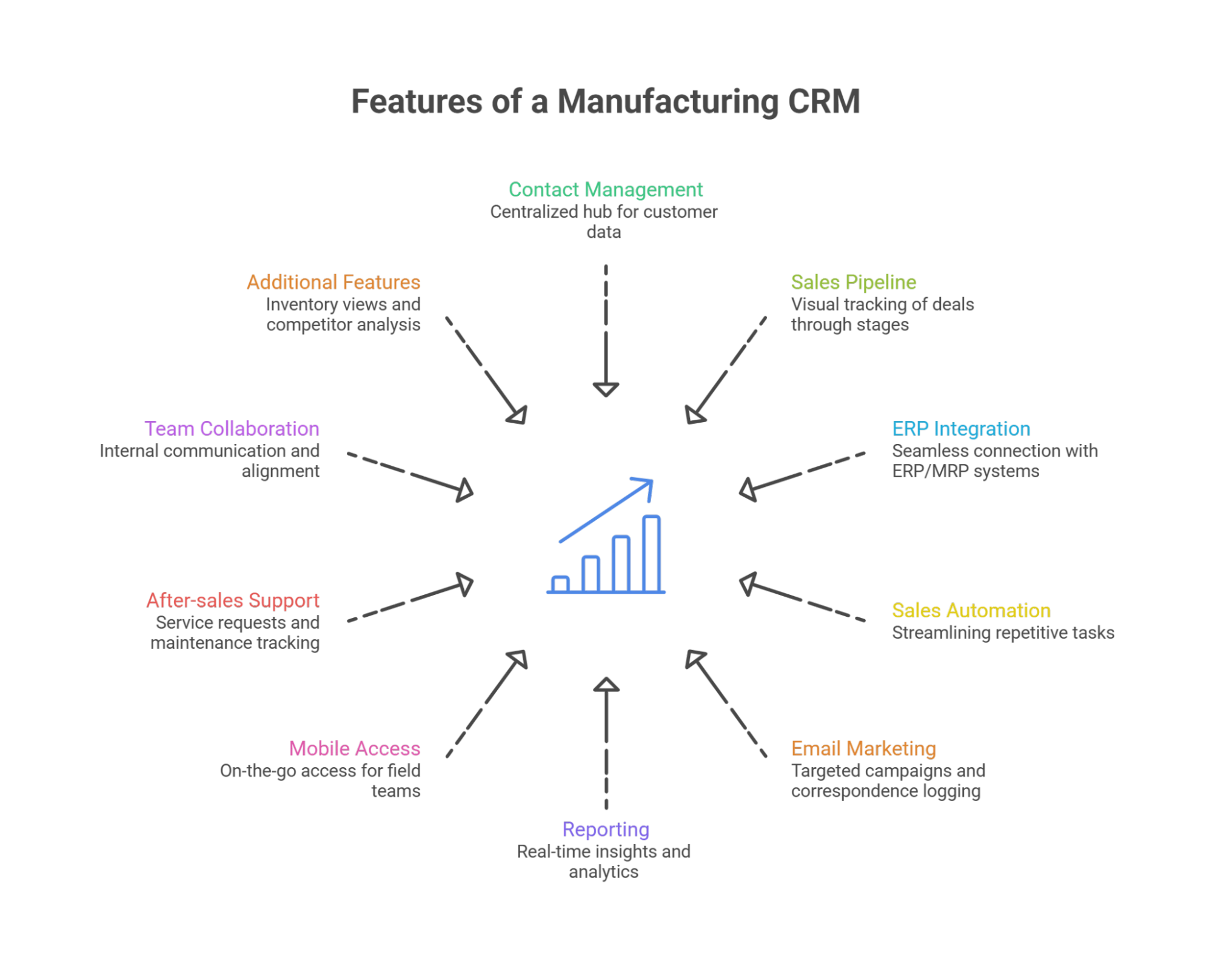

Essential Features of a Manufacturing CRM

A robust industrial CRM customized for manufacturing goes beyond standard sales tools. It incorporates features that align with the industry’s complex processes, long cycles, and need for cross-departmental integration. Below are the key CRM features that can help you close more deals:

-

Contact and Lead Management

This provides a centralized hub for customer, distributor, and prospect data, including details, history, and custom fields (e.g., product preferences). Lead scoring ranks prospects automatically, tracking follows progression, and automated capture imports leads from websites or emails. It ensures no leads are lost and prioritizes high-value opportunities in extended sales cycles.

-

Sales Pipeline and Opportunity Management

Visual pipelines track deals through customizable stages, from inquiry to closure, reflecting manufacturing workflows. Prioritization flags key opportunities, while forecasting uses pipeline data for revenue predictions. This supports accurate production planning and resource allocation.

-

ERP/MRP and Inventory Integration

One of the most critical features for manufacturing, this enables bidirectional integration with Enterprise Resource Planning (ERP) or Material Requirements Planning (MRP) systems. Sales orders flow directly into production schedules, inventory levels update in real time, and stock availability appears during quoting.

-

Sales Automation

Automation streamlines repetitive tasks in long sales processes. Drip campaigns send timed, personalized email sequences to nurture leads. Automated reminders alert teams to follow-ups or approvals, while task assignment distributes activities based on roles or territories. This boosts productivity, ensures consistent engagement, and accelerates deal progression without manual oversight.

-

Email Integration and Marketing Tools

Syncs with email clients to log correspondence automatically. Marketing features segment audiences for targeted, personalized campaigns based on purchase history, improving engagement in B2B settings.

-

Reporting, Analytics, and Dashboards

Customizable dashboards provide real-time views of key metrics like win rates, pipeline health, forecast accuracy, and regional performance. Advanced analytics drill down into trends, such as product demand or customer profitability. These insights support data-driven decisions, identify bottlenecks, and measure ROI on sales and marketing efforts.

-

Mobile Access for Field Sales Teams

Field representatives often visit clients, distributors, or trade events. Mobile apps allow on-the-go access to customer data, pipeline updates, inventory checks, and quote generation. Offline functionality ensures usability in remote areas, with automatic syncing upon reconnection.

-

After-sales Support Tools

Manufacturing products requires ongoing support. These tools log service requests, track warranty status by serial number, schedule maintenance, and maintain resolution histories. Integration with parts inventory ensures quick fulfillment. This feature reduces downtime and captures upsell opportunities during service interactions.

-

Team Collaboration Features

Internal collaboration prevents silos. Users can add notes to records, tag colleagues for input, and view complete communication logs (calls, emails, meetings). Activity feeds show updates in real time. This fosters alignment across sales, production, and service teams.

-

Additional Features

Advanced CRMs include real-time inventory views to avoid selling unavailable stock. Payment and dispatch tracking monitors order fulfillment stages, including invoicing and shipping updates. Competitor analysis logs lost deals, tracks rival mentions, or benchmarks pricing. These extras provide deeper operational control and strategic market intelligence, setting top manufacturing CRMs apart.

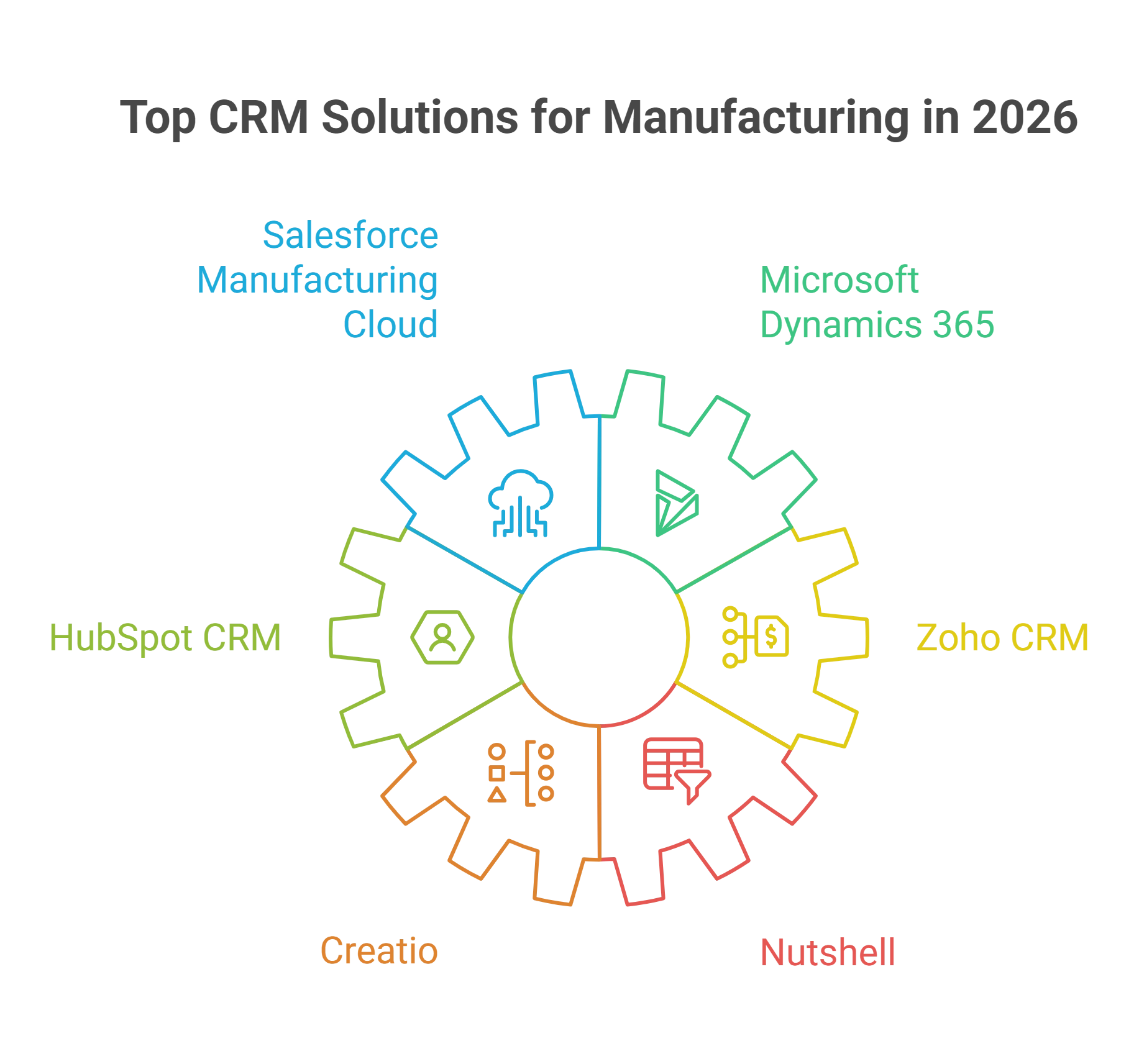

Top CRM Solutions for Manufacturing in 2026

In 2026, the manufacturing CRM landscape will emphasize deep integration with ERP systems, AI-driven forecasting, and support for complex B2B sales cycles. Leading solutions are selected based on manufacturing-specific features, scalability, user adoption, and capabilities in demand planning and after-sales support. Here are the top CRMs for manufacturing industry:

-

Salesforce Manufacturing Cloud

Best for large enterprises needing extensive scalability. Salesforce Manufacturing Cloud excels in AI-powered forecasting (via Einstein), account-based sales agreements, rebate management, and seamless ERP integration. With Salesforce for Manufacturers, they gain unified visibility across sales, operations, and service, with strong tools for channel partner management and predictive analytics.

-

Microsoft Dynamics 365

Best CRM for manufacturing companies seeking integrated CRM and ERP functionality. MS Dynamics 365 provides real-time insights into production, supply chain, and inventory, with Copilot AI for automation and planning. Strong in mixed-mode manufacturing, it supports end-to-end processes from quoting to fulfillment, making it a top choice for mid-to-large firms already in the Microsoft ecosystem.

-

HubSpot CRM

Suited for growing manufacturers prioritizing ease of use and marketing alignment. The free core platform includes robust sales tools, with paid upgrades offering additional automation and reporting capabilities. This best CRM for manufacturing business offers manufacturing templates for pipelines and integrates well with inbound lead management, though deeper ERP ties may require add-ons.

-

Zoho CRM

Affordable and highly customizable for mid-sized manufacturers. Features extensive integrations (including Zoho’s own ERP tools), advanced analytics, and AI (Zia) for predictions. It supports inventory syncing, multi-channel sales, and workflow automation, with strong value for cost-conscious teams.

-

Creatio

Excellent for no-code customization and workflow-heavy processes. Its low-code platform allows tailoring to unique manufacturing needs, like custom order tracking or supply chain automation. Strong in sales, service, and marketing unification, with AI assistance for personalization.

-

Nutshell

Customized for sales-focused B2B manufacturers, especially smaller teams. Intuitive pipeline management, email automation, and reporting shine in handling complex deals and distributor relationships. It’s user-friendly with solid mobile access, ideal for streamlining quote-to-order without overwhelming features.

A Quick Comparison Table

| CRM Solution | Ease of Use | Industry-Specific Features |

| Salesforce Manufacturing Cloud | Requires more training | Leading with pre-built manufacturing modules (e.g., rebate management, channel partners) |

| Microsoft Dynamics 365 | Moderate training needed | Strong pre-built CRM+ERP integration and production visibility |

| HubSpot CRM | Highly intuitive | Good templates; customization via add-ons |

| Zoho CRM | Very intuitive | Extensive customization and integrations |

| Creatio | Intuitive with no-code tools | High flexibility for custom workflows |

| Nutshell | Highly intuitive | Strong for sales pipelines; customization available |

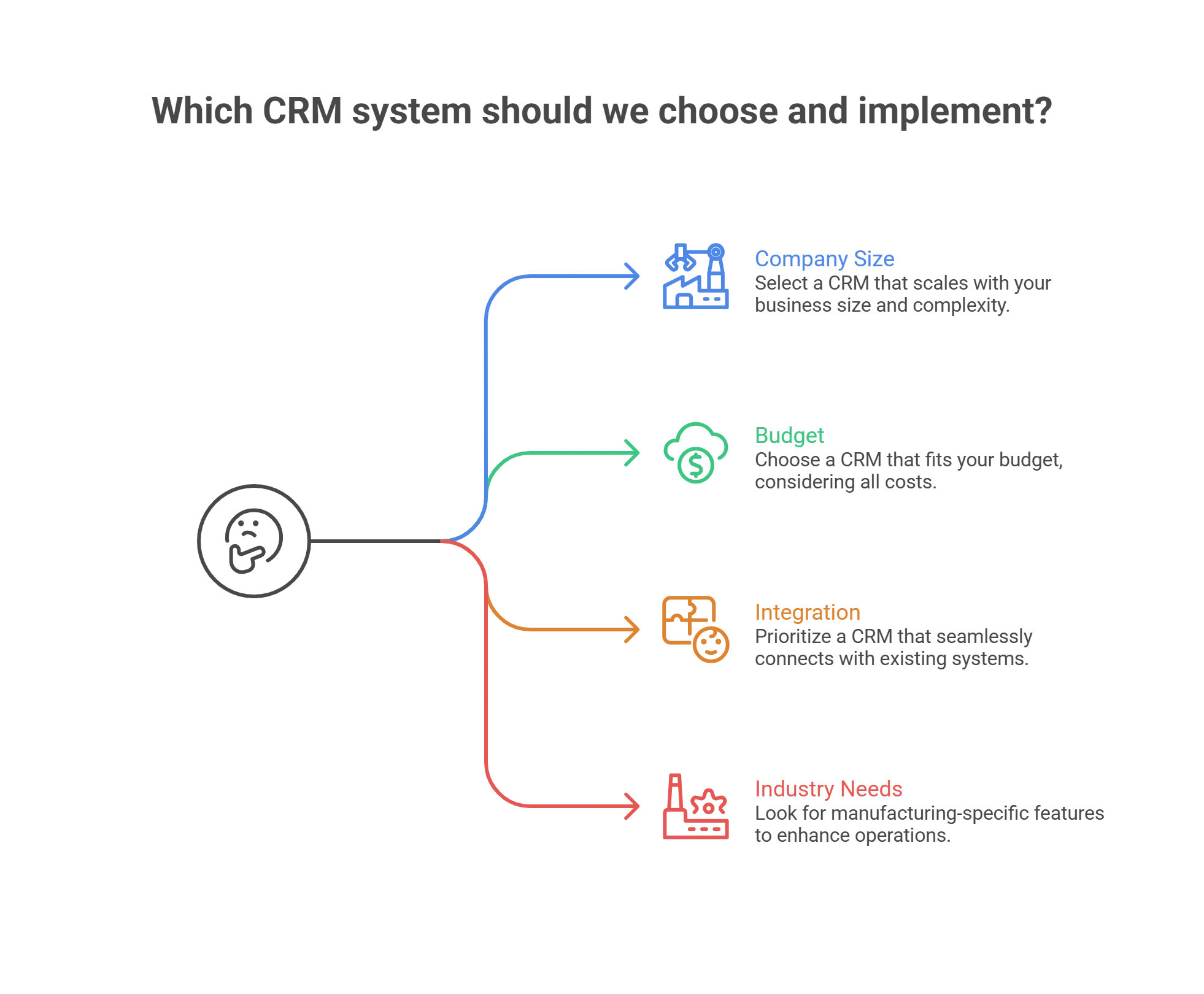

How to Choose and Implement the Right CRM for Manufacturing

Selecting and implementing a CRM system is a strategic decision that can significantly impact manufacturing efficiency and growth. Careful evaluation and structured rollout are key to success.

-

Company Size and Scalability

Small manufacturers may prefer simple, affordable tools like HubSpot or Nutshell. Mid-sized firms often choose customizable options like Zoho or Creatio. Large enterprises need robust platforms like Salesforce Manufacturing Cloud or Microsoft Dynamics 365 that scale with complex operations.

-

Budget

Factor in licensing, customization, implementation, training, and ongoing costs. Free or low-cost starters (HubSpot, Zoho) suit tight budgets, while premium solutions offer deeper features for higher investment.

-

Integration Capabilities

Prioritize seamless connectivity with existing ERP/MRP, inventory, and production systems to avoid data silos.

-

Specific Industry Needs

Look for manufacturing-focused features like real-time inventory visibility, demand forecasting, after-sales tracking, and distributor management.

Challenges in Implementing CRM for Manufacturing

CRM implementation in manufacturing delivers strong benefits but often encounters hurdles due to operational complexity and long-established habits. Teams frequently resist change, clinging to familiar manual tools like spreadsheets or legacy systems, viewing CRM as unnecessary complexity or a threat to their routines.

Many employees lack digital skills, requiring substantial training. Data migration poses another major issue, as legacy records are typically messy, incomplete, or duplicated, making cleaning and transfer time-consuming and prone to errors that undermine system trust.

Additionally, aligning CRM workflows with extended sales cycles, custom orders, and production realities is challenging. Generic setups can create conflicts between sales promises and actual capacity, demanding expert customization. Costs for licensing, training, and integration can exceed budgets, while poor communication and unclear ownership stall progress.

Finally, integrating with ERP or shop-floor systems raises security and compliance concerns, with any disruptions risking production halts. Proactive strategies like leadership backing, early audits, phased rollouts, and specialist support are vital to overcome these and ensure successful adoption.

How Ksolves Can Help with CRM Development and Implementation in Manufacturing

As an expert technology partner with over 12 years of experience in CRM development and implementations, Ksolves delivers tailored solutions for the manufacturing industry across leading platforms. Our customer-centric approach and Agile methodology ensure flexible, high-impact deployments that tackle complex challenges like data migration, workflow alignment, and ERP integration.

We stand out through:

– Deep Expertise: 100+ certified professionals skilled in demand forecasting, inventory visibility, and AI automation.

– Customized Solutions: Optimized setups with real-time inventory, supply chain integration, and unified team views to eliminate silos.

– Seamless Migration & Integration: Expert data cleaning, deduplication, and secure ERP/MRP connectivity with zero operational disruption.

– Training & Support: Full training, change management, phased rollouts, quick wins, and 24/7 global assistance.

– Proven Impact: Boosted sales efficiency, accurate forecasting, higher satisfaction, revenue growth, and strong ROI.

Partnering with Ksolves ensures cost-effective, low-risk implementations with a lasting competitive edge.

Case Studies: Ksolves Success with CRM Implementations in Manufacturing

At Ksolves, we specialize in overcoming CRM challenges through customized manufacturing CRM systems, intelligent automation, and cloud strategies. These real-world examples highlight how we streamline operations, enhance customer engagement, and deliver tangible business growth for our clients.

Reducing Production Delays by 25% in Manufacturing

Client Challenge:

A global manufacturing company faced repeated delays due to disconnected systems and inadequate real-time demand forecasting.

Ksolves Solution:

We implemented Salesforce CRM (including Manufacturing Cloud features) to unify sales, production, and service teams, enabling accurate demand forecasting and faster quoting.

Results:

- 25% reduction in production delays

- 30% improvement in on-time delivery

- 20% boost in order fulfillment efficiency

Enhancing Sales Efficiency with AI-Powered Automation in Manufacturing

Client Challenge:

A global manufacturer struggled with manual handling of high-volume email inquiries, delayed quote approvals, fragmented data across platforms, and a lack of intelligent prioritization.

Ksolves Solution:

We built an AI-driven Salesforce CRM solution using Einstein AI, Agentforce, Flows, Prompts, and Apex to automate inquiry processing, quote generation, lead prioritization, and real-time data retrieval.

Results:

- Significantly faster response times and quote delivery

- Reduced manager dependency for approvals and prioritization

- Higher productivity with smarter task handling

- Improved customer experience and scalability without added staff

Future Trends in CRM for Manufacturing

In 2026 and beyond, CRM for manufacturing is advancing quickly with AI, connectivity, and sustainability at the core.

-

AI and Predictive Analytics

Deeper AI integration for autonomous automation, accurate demand forecasting, predictive maintenance, and smarter inventory using IoT and real-time data.

-

Mobile, Real-Time, and Sustainability Focus

Stronger mobile access for field teams, instant data sync, sustainability tracking (e.g., emissions and eco-practices), and hyper-personalized customer experiences.

-

Hybrid Solutions and Customization

Rise of unified CRM+ERP platforms, hybrid cloud deployments, and industry-specific modules with low/no-code tools for faster, tailored implementations.

These trends make CRM a strategic hub for resilience, efficiency, and competitive growth in manufacturing.

Conclusion

A CRM is essential for manufacturing success in today’s competitive landscape. It centralizes data, eliminates silos, automates processes, and delivers real-time insights, driving better forecasting, efficiency, customer satisfaction, and revenue growth.

Challenges like resistance, migration, and integration can be overcome with proper planning and expert support. As AI, mobile access, and hybrid solutions advance, early adopters will gain lasting resilience.

Partner with experts like Ksolves for smooth, high-ROI CRM development services. Contact us at sales@ksolves.com to transform your manufacturing operations through CRM.

FAQs

Q1. Is CRM only for sales teams in manufacturing?

No. CRM connects sales, production, inventory, and service teams. It improves forecasting, aligns orders with capacity, and supports after-sales service for the whole organization.

Q2. How long does CRM implementation take in manufacturing?

It varies by size. Small to mid-sized firms: 3-6 months. Large enterprises with custom integrations: 6-12 months. Phased approaches with partners like Ksolves speed it up.

Q3. Is CRM worth it for small manufacturers?

Yes. Affordable options like HubSpot or Zoho deliver fast ROI through better leads, productivity gains (10-30%), accurate forecasting, and stronger retention.

Q4. What are the latest trends in CRM for manufacturing?

Key trends include deeper AI for predictive forecasting and automation, stronger mobile access with real-time data, sustainability tracking (e.g., emissions monitoring), and growth of hybrid CRM+ERP platforms with industry-specific customizations.