How Odoo is beneficial in Manufacturing Industries

Odoo

5 MIN READ

June 29, 2022

![]()

Abstract

The process of transforming raw materials into completed products is known as manufacturing. Manufacturing requires several complex operations, and each process may be coordinated using ERP (enterprise resource planning) software.

The market is full of many ERP solutions, and Odoo is one of them. The Odoo Manufacturing ERP Software assists the end-user in managing the complexity of production, such as BOM (bills of materials), planning manufacturing orders, tracking work orders, and more.

Odoo For Manufacturing Industry

When manufacturing companies grow, the management of inbound/outbound operations becomes more dispersed. Odoo ERP for the manufacturing industries is a centralized control system that runs business activities smoothly.

Odoo ERP helps with the automation of operations such as material sourcing, purchasing, inventory, order, accounting, invoicing, and human resource management for manufacturing industries.

Odoo has multiple modules for managing the business effectively. The Odoo Manufacturing Module helps you generate invoices, manage material handling, keep track of product items, and many more.

The manufacturing industry faces many challenges like any other industry. With Odoo Manufacturing or MRP, you can overcome these challenges to manage your business workflow.

Let’s find out the common challenges of the Manufacturing Industry.

7 Challenges of Manufacturing Industries

-

Demand Forecasting

Demand forecasting is the fundamental tool used by manufacturers to properly calculate the ideal supply rate and create appropriate resources to minimize expenditures. However, sometimes is it complex to calculate the actual demand for a month/year due to multiple factors. The demand can be low or high due to a lot of changes in every parameter. Improper demand forecasting is a major challenge for any manufacturing industry to estimate how many goods they need to sell.

-

Managing Inventory

Managing an inventory manually can affect the ROI (return on investment) due to data inaccuracies, stocking difficulties, and poor judgments. If a manufacturer has difficulties keeping track of inventory, it may lead to shortages and other problems.

-

Cost-cutting and Efficiency Enhancements

Reducing manufacturing costs while keeping a healthy, effective supply chain is one of the simplest ways to double the profits. Manufacturing companies must embrace automation in operations and management to reduce manufacturing costs and increase efficiency.

-

Maintaining Machine Efficiency

Manufacturing companies need to manage the efficiency of their machinery. Machine maintenance is an essential component of any product manufacturing process. Businesses with worn-out machinery will not be able to operate at full capacity. Their capacity for manufacturing will eventually decline. As a result, the manufacturing company needs to perform frequent machine maintenance procedures. Regular maintenance lead to production delay hence affecting the entire manufacturing business.

-

Total Manufacturing Cost (Actual Cost of Product)

In the manufacturing industry, it is necessary to find the actual cost of the product. Total manufacturing cost is the sum of all expenditures involved in the process of producing a final product. Total manufacturing cost calculation necessitates a precise examination of your company’s many departments to determine how they contribute to the manufacturing process and the related expenses.

The total cost of manufacturing a product varies from the shipping cost, variability in production, multiple supply chain, tax, contract length, and more. Keeping every aspect in mind to find out the actual cost of the product is the real challenge any manufacturing industry faces.

- BOM Challenge

Many manufacturing companies work on the fixed Bill Of Material (BOM). However, custom manufacturers rely on the BOM for a multitude of reasons, from purchase to final product completion. With all of the moving parts in the engineer-to-order process, creating an accurate BOM on the first try may be challenging. The BOM is keep on changing as it is based on the demand of the customers. Therefore, it becomes complex to manage the BOM of variable custom products without having the right ERP software.

-

Tracking Labor Logs

While automation and robotics can help shrink the labor gap, skilled labors will still be required to analyze, solve, and manage challenges. Manufacturing companies need to manage their labor logs to maintain their production flow. It becomes challenging to keep a record of labor logs for each day on paper. Moreover, it can lead to improper payslip management for each employee.

- The solution is the Odoo MRP module. With the implementation of Odoo ERP in your manufacturing company, you can overcome the challenges mentioned above. From managing inventory to BOM to predictive analytics to cutting manufacturing costs, you can manage your business easily.

So, let’s take a look at some of the features of the Odoo MRP module that may help you remain ahead of the competition.

Odoo MRP Features For Manufacturing Industry

Odoo Manufacturing assists you with scheduling, planning, and processing manufacturing orders. Implementing Odoo in a Manufacturing Company will help you with the following features:

-

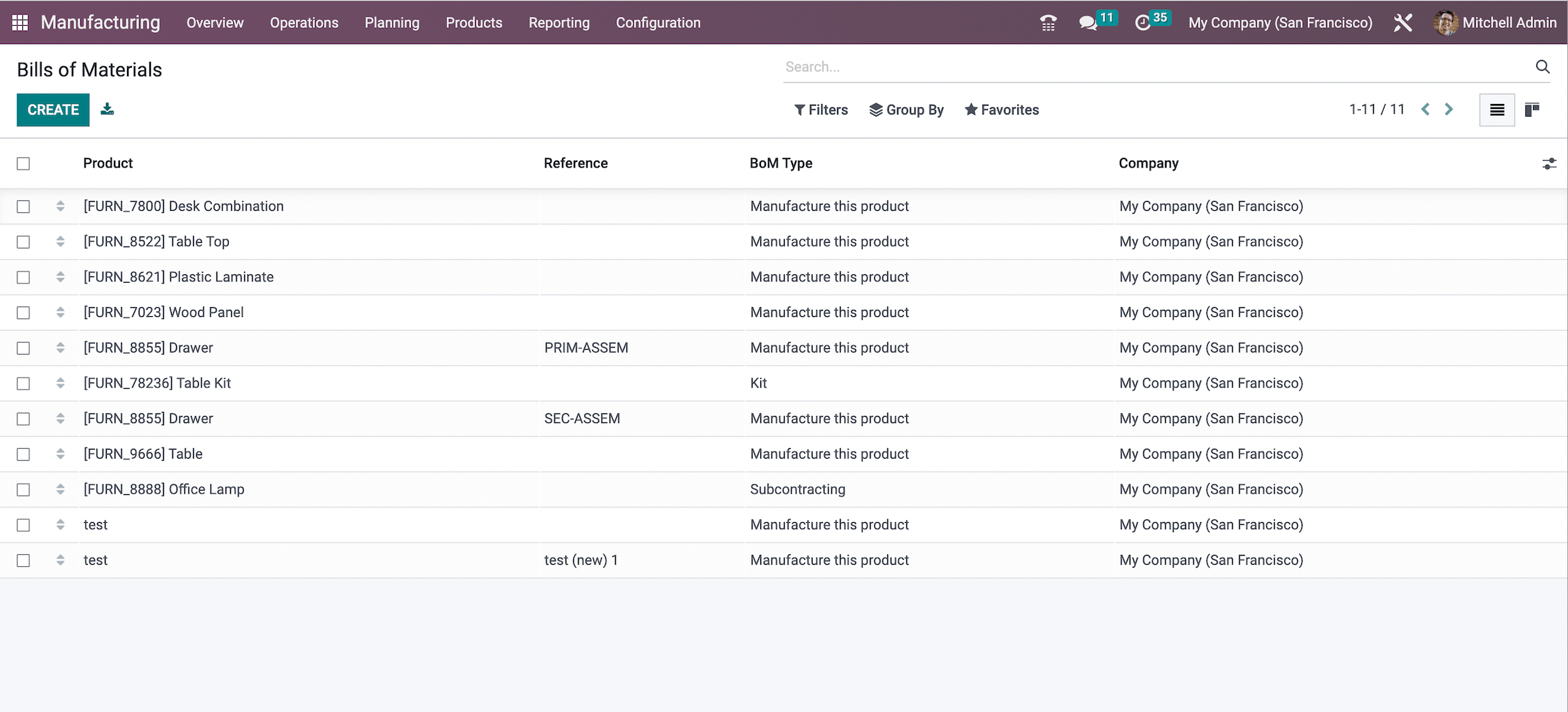

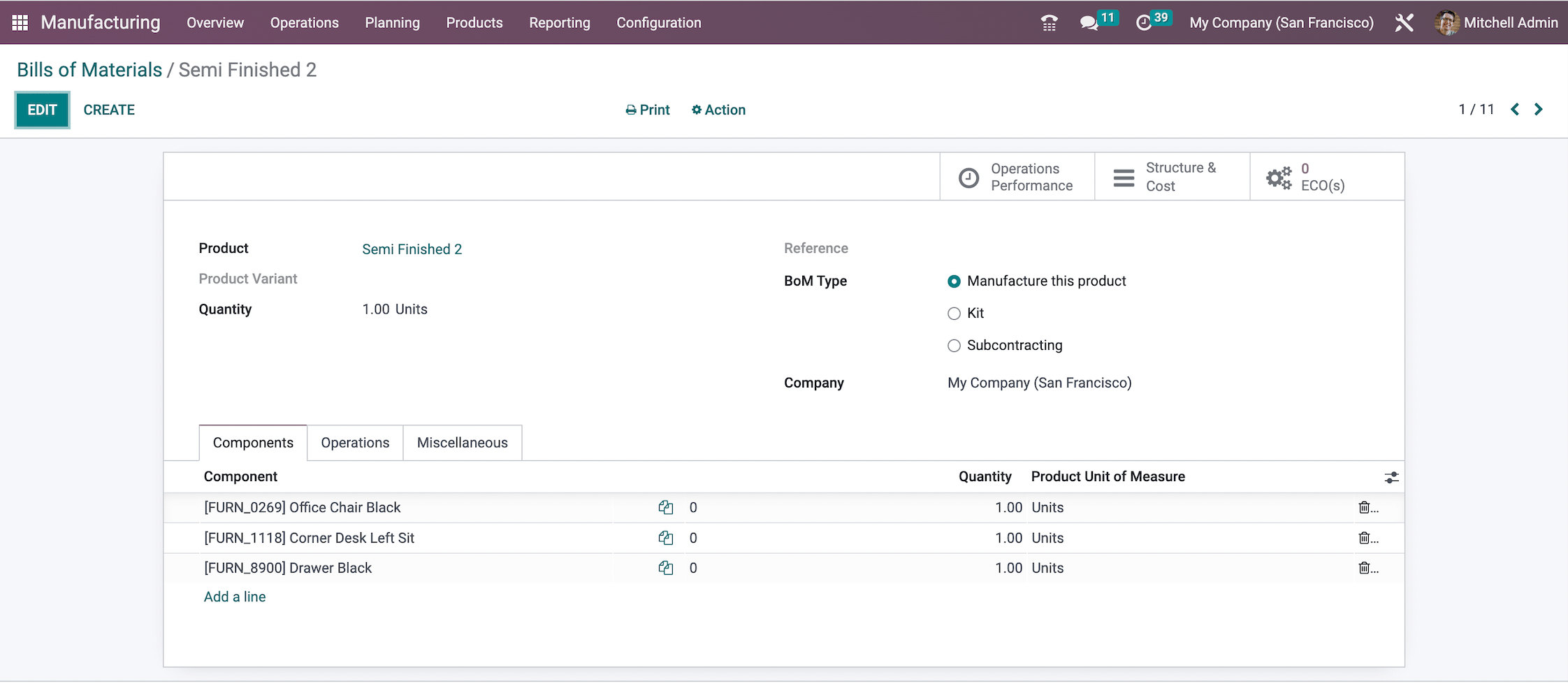

Create Bills of Materials

A Bill of Materials (BOM) is essential in the manufacturing business. It helps manufacturers in maintaining product quality. Odoo also assists users in managing product pricing based on raw material costs.

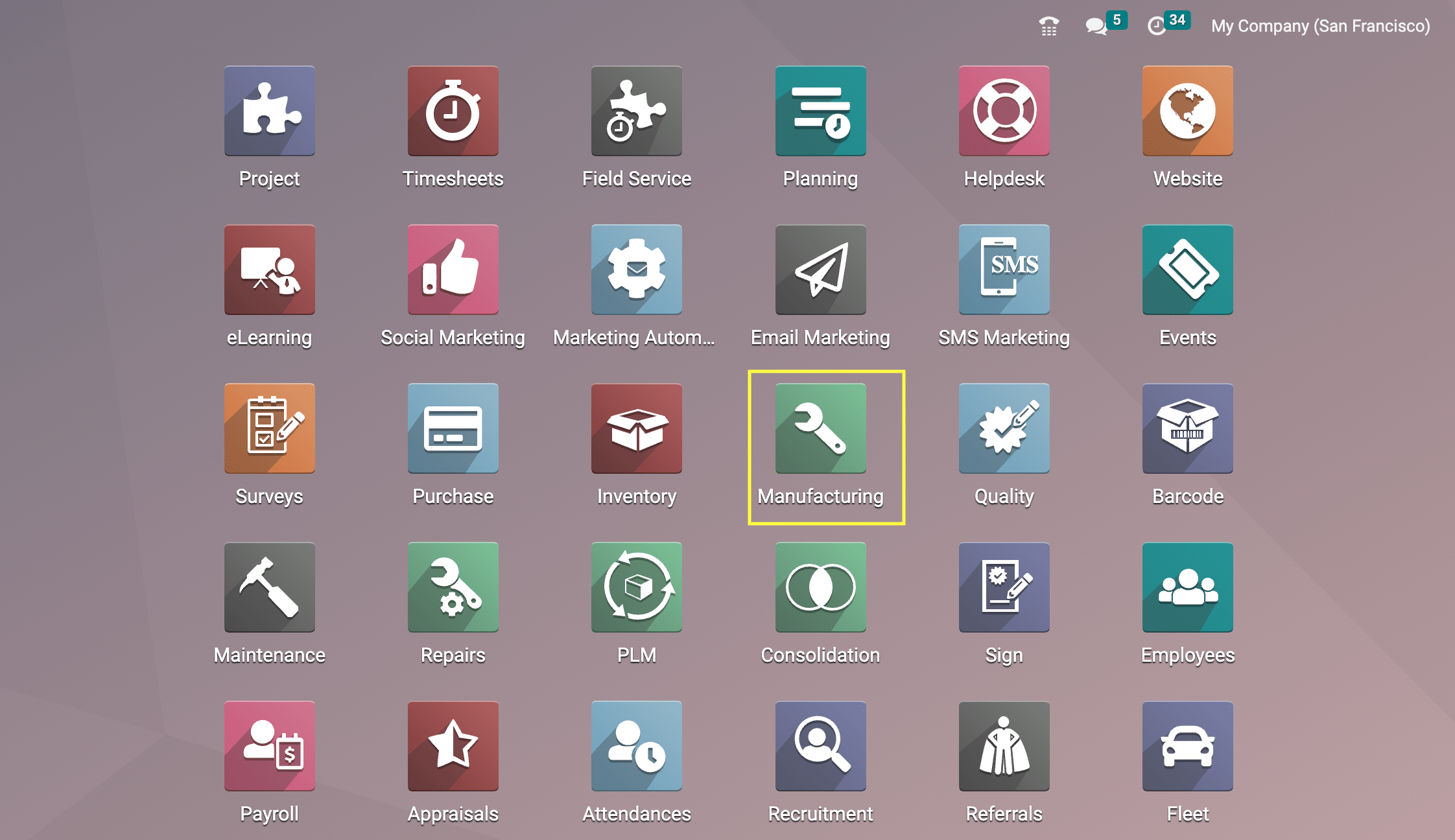

You can create a bill of materials in the Odoo Manufacturing ERP as given below:

Manufacturing→Products→Bills of Materials→Create

Multiple BOMs may be linked to each product using Odoo’s MRP solution, allowing product variations to have their own customized BOM.

-

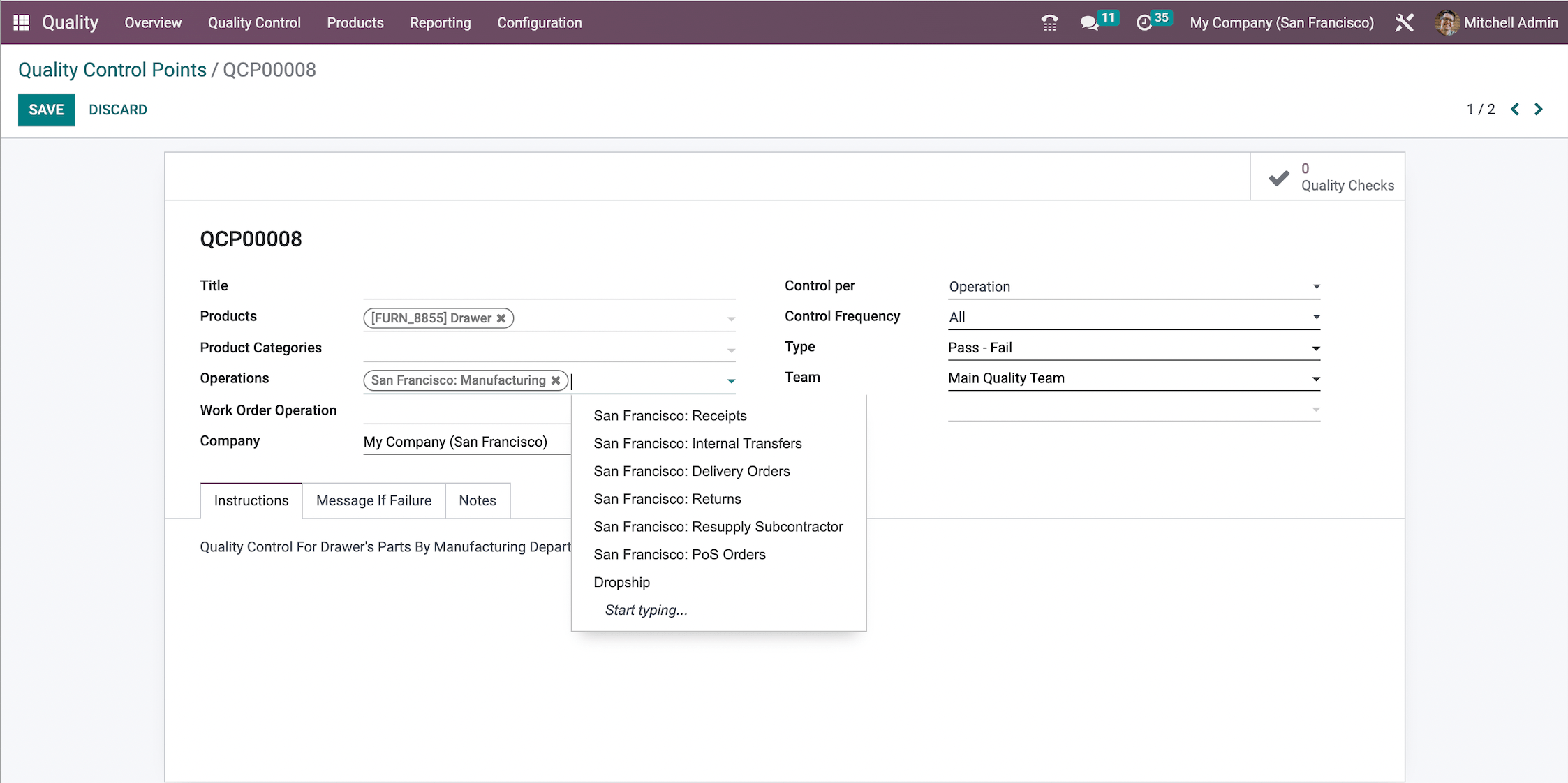

Quality Control

With Odoo’s Quality Control, you can control the quality of the production or production of the subcontractors.

Set Quality Control Point on the Manufacturing Operation Type as shown below to manage the quality of your production.

To know how to create a quality control point in Odoo ERP for the Manufacturing Industry, consult with our Odoo experts. Take a FREE DEMO now!

-

Management of Semi-Finished Products

Semi-finished product is a part of the main product. Combining the required semi-finished products, the main product is built. Semi-finished products are also identified as sub-assemblies.

With Odoo ERP for Manufacturing Management, you can simplify complex Bill of Materials, which makes the manufacturing process error-free.

A multi-level BOM is a bill of materials that deals with sub-assemblies.

In Odoo ERP MRP Module, a multi-level bill of materials is built by first creating a subassembly bill of material and then a top-level bill of material. As a result, when a manufacturing order for a complete product is produced, it also creates a manufacturing order for sub-assembly.

To create the sub-assembly items and their BOMs, refer to our technical expert’s advice!

-

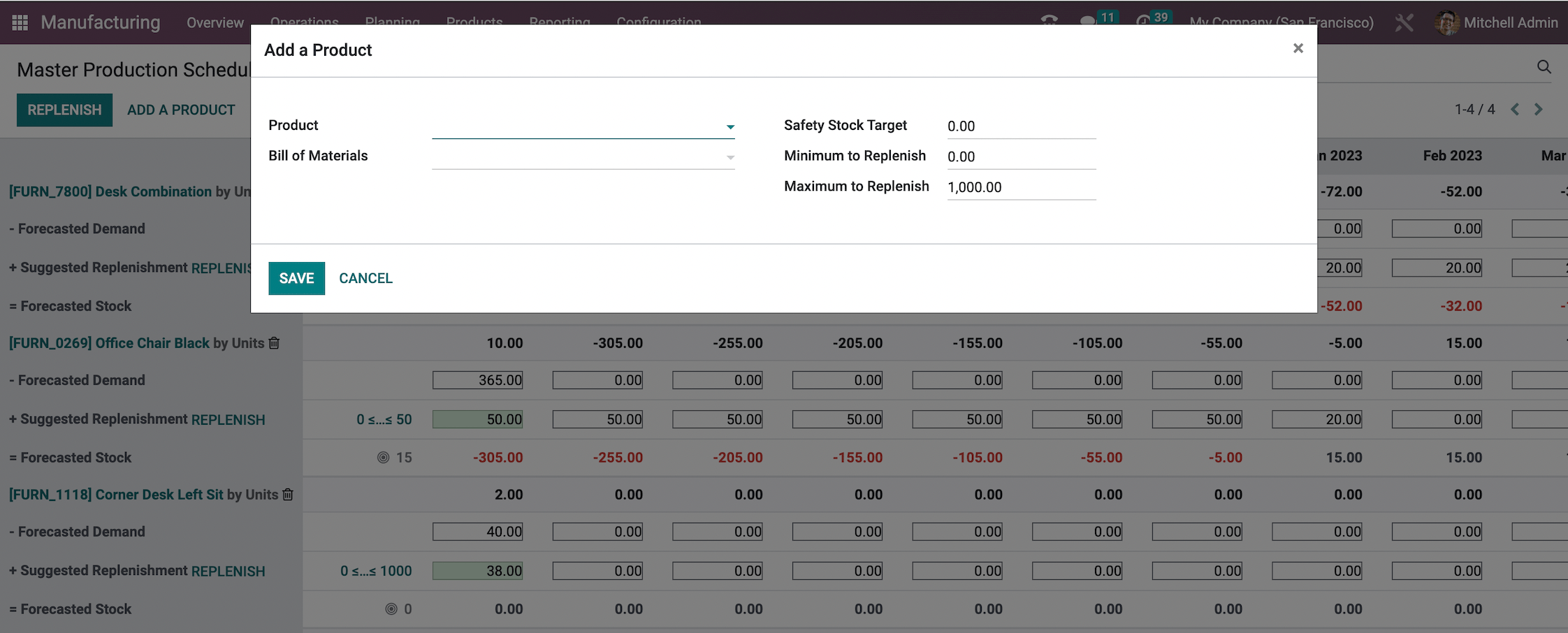

MPS (Master Production Schedule) in Odoo

Based on the demand forecast, manufacturing companies can plan their production using the MPS tool in Odoo.

Many times manufacturers produce products in bulk without knowing the demand in the market. Using the Master Production Schedule, plan production in an effective way without affecting your resources.

You can plan production in Odoo MRP by the following settings as given below:

→Enable the MPS: Go to Manufacturing> Configuration> Settings> Planning and Enable MPS (Master Production Schedule).

→Plan Production: Go to Manufacturing> Planning> Click on Master Production Schedule. You will get a window like this:

You can add the product type and other details as required. Moreover, in MPS, you can decide which information you would like to showcase by selecting from the Rows list.

Have trouble managing the production for your manufacturing industry in advance? Consult with Ksolves today!

-

Alternative Work Centers

The WorkCenters in the manufacturing industry must be planned properly. Unmanaged work centers for each production process can affect the company’s revenues. With Odoo MRP management, you can create alternative work centers to make the manufacturing process more efficient.

-

Subcontract the Manufacturing

If you require to outsource some of the manufacturing parts, you can keep track of that with Odoo ERP. Odoo is a boon to the manufacturing industry, as it provides what is required to run a business smoothly.

Outsourcing the part of your company’s manufacturing becomes easy with Odoo Manufacturing Module Implementation. Handle your company’s outsourcing process easily with Odoo ERP.

-

Manage Kits in Odoo

Many times, the manufacturing industry has to sell products as a Kit. A Kit contains multiple components that form a complete product. However, if you are selling multiple products in a Kit, the inventory for individual components needs to be managed.

One of the features of Odoo MRP is the Kit that comes under the BOM type, which allows you to combine multiple products under a single list. Additionally, when an inventory adjustment is made on the kit, the inventory of individual goods is automatically updated.

-

Variants BOM Management

If you need to manage a single Bill of Materials for multiple variants of the same product, you can do it by enabling the Variants in Odoo. This is one of the amazing features of Odoo Manufacturing ERP Software.

Looking to scale your manufacturing business with Odoo MRP? Let us give you lifetime support on that! Take Manufacturing ERP implementation services today!

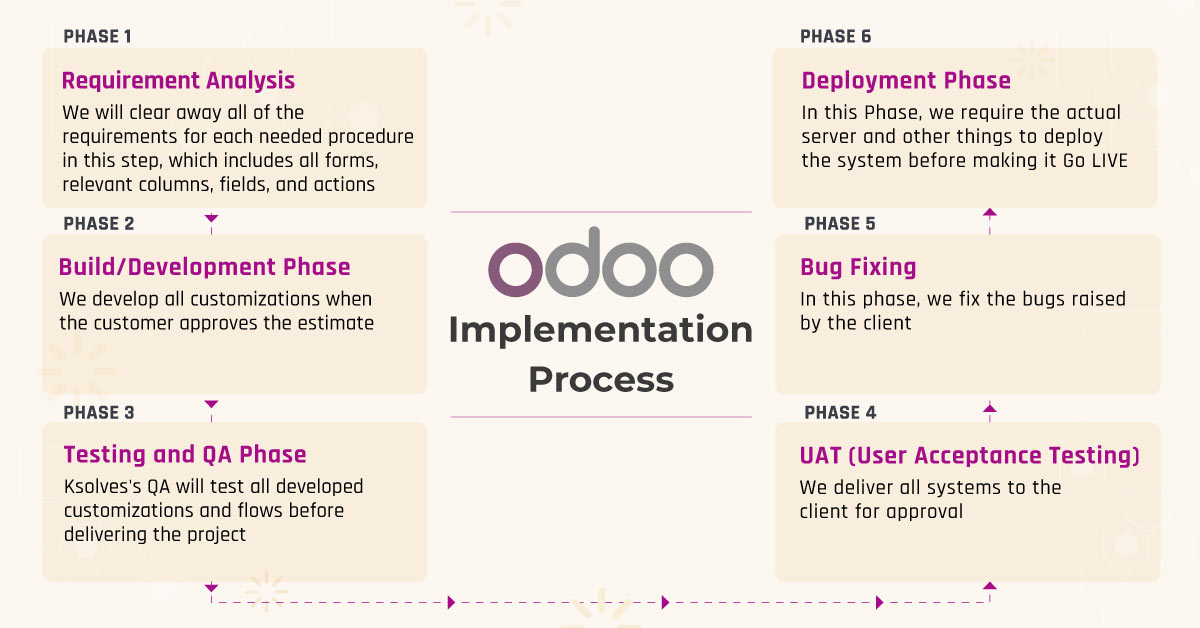

Ksolves Implementation Process

Ksolves follows a standard Odoo ERP Implementation processto help businesses grow.

Let’s understand from the given image the steps involved in the Ksolves Implementation Process for the manufacturing industry.

→ Case Study:

Ksolves helps the PCB Manufacturer company to streamline its workflow, eliminate duplicate product records, managing inventory for multiple products.

Ksolves team of experts is experienced in creating the right strategy for the Manufacturing industry. For our PCB manufacturing client,

- We created a configuration form called “Product Configurator” in which the customer simply needs to enter the product’s specifications. It eliminates the issue of duplicate products.

- We also created a vendor and customer gateway so that our client’s sales staff could simply discover the appropriate source for a given product.

Our years of experience in the Manufacturing industry help businesses precisely manage their work processes.

Our Odoo Implementation Team develops a solution that helps the client to manage its manufacturing business easily without losing any important data. Click here to read the entire case study published on the Ksolves website!

Manufacturing Industries Catered by Ksolves

Ksolves have catered to many manufacturing industries with its outstanding Odoo ERP implementation services. From Construction to PCB to Food to LED and more, our team has helped many companies streamline their business processes.

If you need to improve the workflow of your Manufacturing company, get in touch with our Odoo experts today!

Why Choose Ksolves?

Ksolves have a team of certified Odoo experts. Our Odoo MRP development team is helping businesses to stay competitive in the market. We have expertise in the LED industry as well. Where we helped the client with a customized Odoo solution for streamlining its business.

Our manufacturing expertise does not end here, we have helped Door & Window manufacturing company in running their business effectively with Odoo Implementation. Through our Odoo implementation team, we matched the client’s complete company workflow to the framework of Odoo ERP. Starting with a lead generating form that allows rapid quotation approval with import and export options so that the data may sync to other software immediately.

We are CMMI Level 3 certified company. Tell us your query and we will give you the cutting-edge solution for the same.

Need Odoo MRP Implementation services? Connect with us at:

Email: sales@ksolves.com

Call: +91 8130704295

Frequently Asked Questions

1. What can Odoo deliver to a Manufacturing Industry?

Odoo MRP can help a manufacturing company to manage all the processes from procurement to distributing raw material. You can easily manage multiple manufacturing processes with the Odoo MRP system.

2. Is Odoo good for manufacturing?

Odoo assists the manufacturing industry to speed up its production process. With Odoo ERP, manufacturing companies can monitor production costs and future requirements.

3. Which manufacturing companies Ksolves have worked for?

Ksolves has a year of expertise in dealing with the challenges of manufacturing companies. We have catered to the PCB manufacturing industry, Doors & Windows manufacturing industry, LED, and more industries. Connect with us to overcome the challenges of your manufacturing company with our team of experts.

![]()

AUTHOR

Odoo

Neha Negi, Presales and Business Associate Head at Ksolves is a results-driven ERP consultant with over 8 years of expertise in designing and implementing tailored ERP solutions. She has a proven track record of leading successful projects from concept to completion, driving organizational efficiency and success.

One thought on “How Odoo is beneficial in Manufacturing Industries”

Leave a Comment Cancel Reply

Your blog is best. Thanks for sharing with us.