Food Safety Compliance with Odoo: Reducing Risks and Enhancing Quality

Odoo

5 MIN READ

February 6, 2026

![]()

Ensuring food safety today isn’t just about following regulations but a brand‑defining mission that directly impacts consumer trust, profitability, and the very survival of food businesses. With over 600 million people worldwide falling ill from contaminated food each year and more than 400,000 deaths, food safety remains one of the most pressing global health challenges for the food and beverage industry.

The stakes are high: a single recall can cost manufacturers millions of dollars, erode long‑built customer loyalty, and send shockwaves through supply chains. In fact, roughly 23% of food recalls can cost a business $30 million, and many firms face even higher losses when brand damage and operational disruptions are factored in.

Traditional, manual approaches to compliance, such as relying on spreadsheets, disparate records, and siloed teams, simply can’t keep pace with the complexity of modern regulations and consumer demands. This is where Odoo ERP steps in. It is a centralized, modular platform that not only helps food businesses stay compliant but also reduces risks and enhances quality across the entire value chain.

In this blog, we’ll explore how Odoo supports food safety compliance, streamlines operations, and helps organizations protect their customers and their reputation.

Why Food Safety Compliance Matters

Food safety compliance means adhering to globally recognized standards such as ISO 22000, HACCP, FSSAI, and FDA regulations to ensure that every product reaching consumers is safe, consistent, and high quality. These frameworks are designed to prevent risks at every stage, from sourcing raw materials to final distribution.

When compliance breaks down, the consequences can be severe:

- Public Health & Legal Risk: Product contamination leads to serious health crises and significant legal exposure.

- Financial Impact: Costly recalls and regulatory penalties can jeopardize annual profitability.

- Reputational Damage: Loss of consumer trust is often harder to recover than financial loss.

- Operational Waste: Inefficient tracking leads to expired inventory and higher production costs.

But food safety compliance goes beyond simply meeting regulatory checklists. It’s about building a proactive, preventive quality culture – one that continuously monitors processes, identifies risks early, and ensures transparency across the entire supply chain.

Also Read: Conquer Food Distribution Complexity with ERP

Benefits of Using Odoo for Food Safety Compliance

- Reduced Compliance Risks

- Consistent Product Quality

- Audit-Ready at All Times

- End-to-End Traceability

- Compliance Without Extra Effort

- Stronger Brand Trust

How Odoo Supports Food Safety Compliance

Odoo is a modular, end-to-end ERP platform built to unify every function of a food business, including procurement, production, quality, inventory, and distribution, within a single system. Instead of managing compliance through disconnected tools and manual records, Odoo embeds food safety controls directly into everyday operations.

By leveraging the right combination of Odoo modules, food businesses can:

- Automate compliance-driven workflows, reducing dependency on manual checks and paperwork.

- Maintain accurate, audit-ready records with complete batch-level traceability.

- Monitor and enforce quality standards at every stage of the production lifecycle.

- Minimize human error and operational risks through standardized, system-led processes.

This integrated approach ensures that food safety is not treated as a separate activity, but as a built-in part of how the business operates every day.

Below is a breakdown of the key Odoo modules that play a critical role in achieving and sustaining food safety compliance.

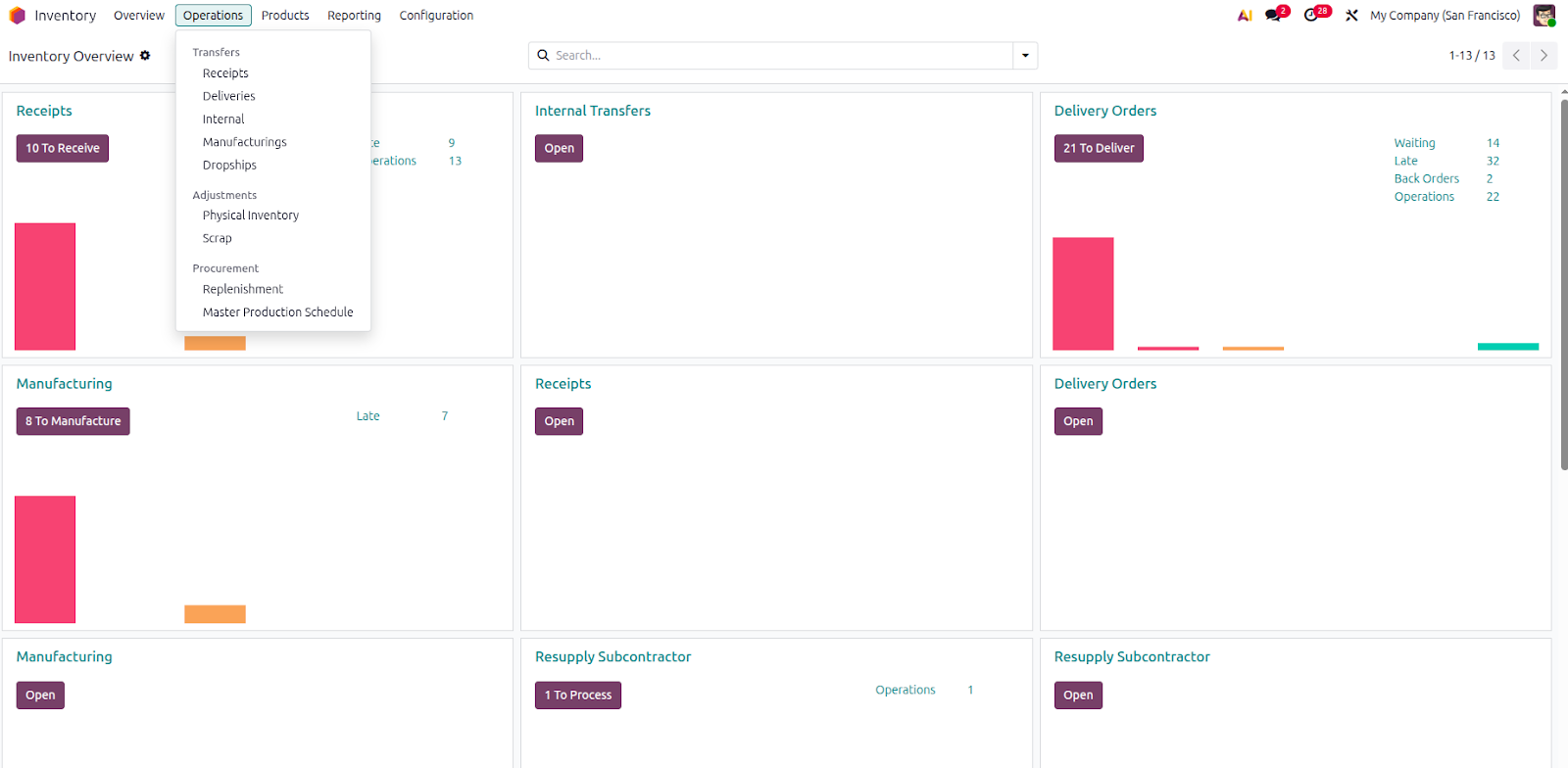

1. Odoo Inventory Management

Effective inventory management is the foundation of food safety compliance. Without clear visibility into stock movement, expiry dates, and storage conditions, food businesses risk spoilage, contamination, and regulatory violations. Odoo’s Inventory Management module provides real-time control and traceability that are essential for meeting food safety standards.

With Odoo Inventory, businesses can:

- Track raw materials and finished goods in real time, ensuring full visibility across warehouses and locations.

- Monitor batch and lot numbers, expiry dates, and shelf life, helping prevent the use or dispatch of expired products.

- Apply FIFO or FEFO stock rotation rules, reducing spoilage and ensuring products are consumed or shipped within safe timeframes.

- Manage perishable and temperature-sensitive items with structured inventory workflows that lower contamination risks.

Every inventory movement, such as receipts, internal transfers, and dispatches, is automatically logged and time-stamped, creating a complete audit trail. This level of traceability is critical during food safety audits, inspections, and product recalls, allowing businesses to respond quickly, accurately, and with confidence.

Also Read: Top 5 Odoo Inventory Apps for 2025

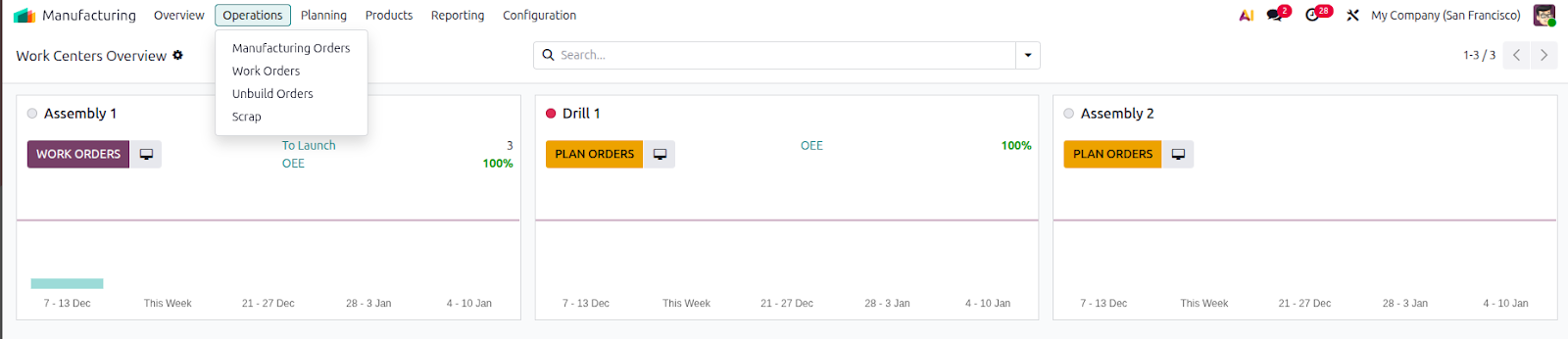

2. Odoo Manufacturing (MRP)

Food safety compliance heavily depends on how consistently and accurately production processes are executed. Odoo’s Manufacturing (MRP) module ensures that every stage of production follows predefined, compliant workflows, reducing variability, human error, and safety risks.

With Odoo Manufacturing, businesses can:

- Define and enforce Standard Operating Procedures (SOPs) by structuring production steps within bills of materials and work orders, ensuring processes are followed exactly as approved.

- Enable batch and lot-level tracking, linking raw materials, intermediate components, and finished products for complete production traceability.

- Manage work orders efficiently, balancing production timelines while maintaining strict quality and safety standards.

- Maintain digital production logs automatically, capturing who produced what, when, and how, critical data for audits and regulatory inspections.

By embedding compliance directly into production workflows, Odoo Manufacturing minimizes deviations that can lead to contamination, rework, or non-compliance. The result is consistent product quality, greater operational control, and audit-ready manufacturing operations.

Also Read: Odoo for Manufacturing: Proven Strategies To Manage Production

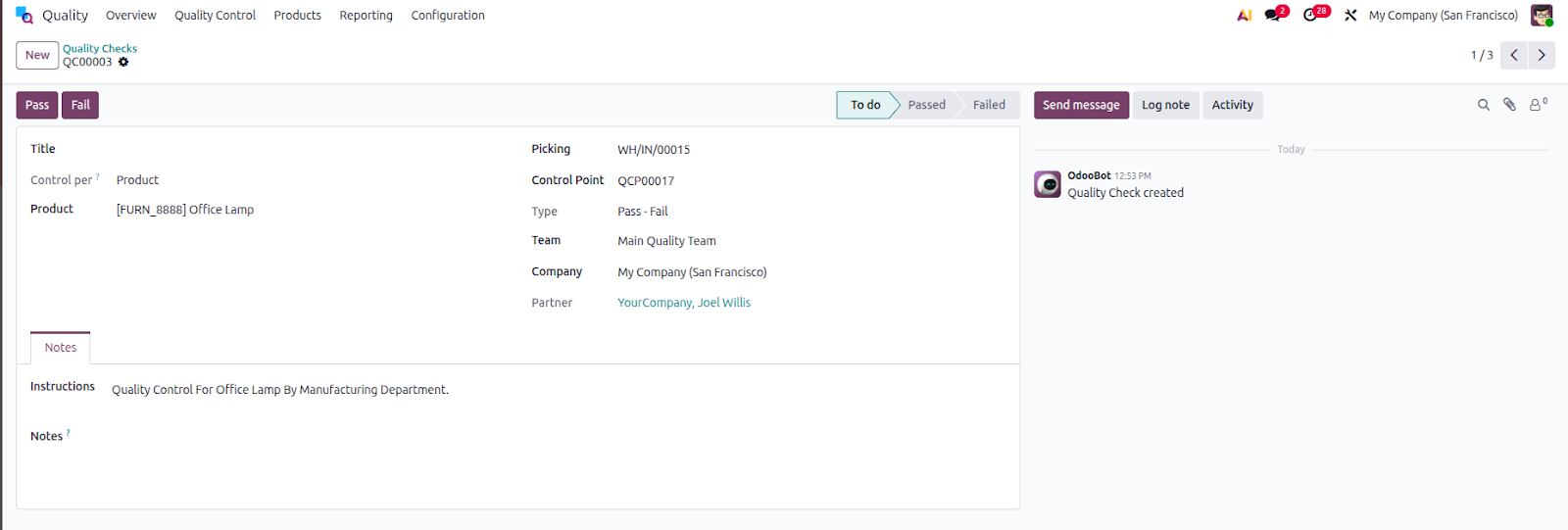

3. Odoo Quality Control

Quality assurance is at the core of food safety compliance. Without systematic checks at the right points, issues can go unnoticed until they reach customers. Odoo’s Quality Control module enables food businesses to move from reactive inspections to proactive, process-driven quality management.

With Odoo Quality Control, organizations can:

- Define inspection points at every critical stage, such as incoming raw materials, in-process production, and finished goods, ensuring risks are identified early.

- Set predefined quality parameters and tolerances, triggering automated alerts when batches fail to meet safety or quality standards.

- Capture and store digital inspection records, creating audit-ready compliance documentation with full traceability.

- Integrate quality checks directly with Manufacturing and Inventory, ensuring non-conforming products are automatically blocked, quarantined, or reworked before they move forward.

By embedding quality control into daily operations, Odoo enables continuous monitoring and faster corrective action. It significantly reduces the risk of unsafe or non-compliant products reaching the market while maintaining consistent product quality.

4. Odoo Traceability

End-to-end traceability is a non-negotiable requirement for food safety compliance and consumer protection. In the event of contamination, mislabeling, or regulatory concerns, businesses must be able to quickly identify affected products and take immediate action. Odoo’s Traceability capabilities provide complete visibility across the entire food supply chain.

With Odoo Traceability, businesses can:

- Track raw materials from approved suppliers through every production stage, ensuring source transparency and accountability.

- Trace finished products across warehouses, distribution channels, and customers, enabling full downstream visibility.

- Execute fast, targeted recalls, isolating only the affected batches rather than disrupting the entire supply chain.

- Maintain a complete batch and lot history, including supplier details, production timelines, and quality inspection results – all accessible in a few clicks.

This level of traceability creates end-to-end transparency, simplifies regulatory reporting, and ensures businesses can respond confidently to audits, inspections, or recall situations, protecting both consumers and brand reputation.

5. Odoo Purchase & Vendor Management

Food safety compliance begins long before production starts, at the supplier level. Using non-compliant or poorly vetted raw materials can compromise product safety and expose businesses to serious regulatory risks. Odoo’s Purchase and Vendor Management module ensures that compliance is enforced right from the sourcing stage.

With Odoo Purchase & Vendor Management, businesses can:

- Maintain an approved vendor list, ensuring suppliers meet defined food safety and regulatory standards.

- Track supplier certifications, quality performance, and audit history, creating accountability and transparency.

- Validate incoming raw materials against predefined quality and safety criteria, reducing the risk of contamination at the source.

By controlling supplier compliance within the ERP system, businesses significantly reduce upstream risks, strengthen supply chain integrity, and ensure only safe, compliant ingredients enter the production process

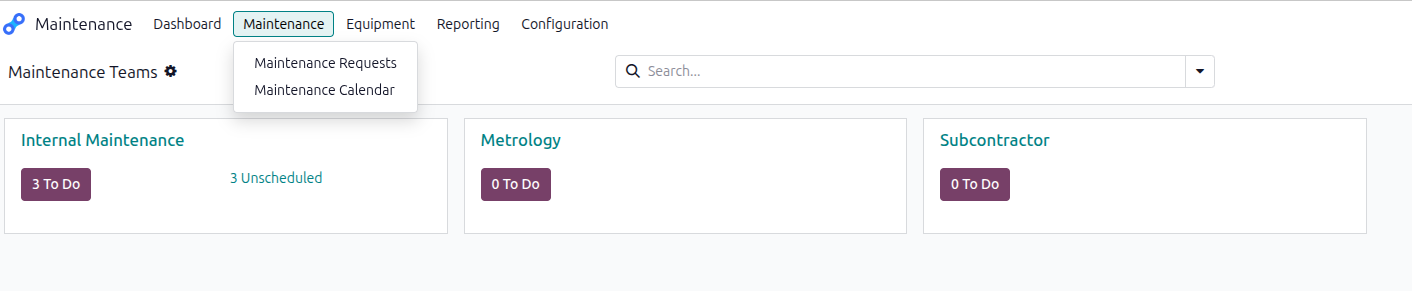

6. Odoo Maintenance

Equipment reliability plays a critical role in maintaining food safety and product quality. Poorly maintained or uncalibrated machinery can lead to contamination, inconsistent production, and regulatory non-compliance. Odoo’s Maintenance module helps food businesses take a proactive approach to equipment safety.

With Odoo Maintenance, organizations can:

- Schedule routine inspections and preventive maintenance for all production and processing equipment.

- Track calibration, sanitation, and cleaning schedules, ensuring machinery meets hygiene and safety requirements.

- Identify and address equipment issues early, reducing downtime and contamination risks.

By integrating maintenance activities with manufacturing operations, Odoo ensures that food safety compliance is embedded across equipment, processes, and people, rather than treated as a separate or reactive task.

How Ksolves Helps You Achieve Food Safety Compliance with Odoo

Implementing Odoo for food safety compliance goes beyond activating modules – it requires the right strategy, configuration, and industry expertise. Ksolves, a trusted Odoo Implementation Partner and Best Partner India, helps food and beverage businesses turn Odoo into a compliance-ready ERP system aligned with regulatory and quality requirements.

We configure Odoo modules to support batch and lot traceability, quality checkpoints, FEFO/FIFO inventory controls, and audit-ready reporting, ensuring food safety is built into everyday operations. Our team customizes Odoo to fit complex food workflows, from supplier compliance to production and distribution.

With end-to-end implementation, customization, and ongoing support, Ksolves ensures your Odoo system reduces risks, simplifies audits, and consistently delivers safe, high-quality products.

Conclusion

Food safety compliance is no longer a one-time requirement but a continuous responsibility that directly impacts consumer trust, brand reputation, and operational stability. As regulations tighten and supply chains grow more complex, food businesses need systems that proactively manage quality, traceability, and compliance at every stage of operations.

Odoo’s integrated modules provide a strong foundation for achieving this, embedding food safety controls into inventory, manufacturing, quality, and supplier workflows. With the right implementation partner like Ksolves, organizations can reduce compliance risks, simplify audits, and consistently deliver safe, high-quality products with confidence.

Want to know how Odoo can transform your business?

![]()

AUTHOR

Odoo

Neha Negi, Presales and Business Associate Head at Ksolves is a results-driven ERP consultant with over 8 years of expertise in designing and implementing tailored ERP solutions. She has a proven track record of leading successful projects from concept to completion, driving organizational efficiency and success.

Share with